stick welding rods chart

stick welding rods chart

If you do not know what type of metal you are dealing with, Weldpundit has an in-depth article on metal identification. You dont have a 115 volt mig welder but you do have a small stick welding machine. You can use them for hard to weld situations such as the following: The basic flux of an E7018 rod protects the weld metal from nonmetallic inclusions caused by oxygen. Informatikai szakmai anyagok (Felhasznli-, s zemelteti Manulok, Szablyzatok, Szerzdsek stb.) According to that, you may have restrictions on the rods you can use. 2015. jlius 23. If you weld joints with a tight fit-up, for instance, square joints without a root gap or beveling, cellulosic rods are more suitable. E6010 In parts of Europe its referred to as MMA or manual metal arc welding. First of all , lets get some terminology straight. 2015. szeptember 08. Finally, you might miscalculate an amperage selection factor and end up with the wrong amperage. They produce a slag that is not easy to remove and requires a lot of cleaning between the passes. You should always choose a rod size thinner than the base metal. What Is the Easiest Stick Welding Rod to Use?  If the workpiece (or base metal) has coatings, for instance, galvanized steel, paint, rust, or other forms of dirt, you should remove it. A circular or side-to-side motion can be used to build up weld or, because of the light flux coating, these rods can be stepped to provide maximum penetration. Munkjval szemben minsgi kifogs mig nem volt. For low-hydrogen welding, you also need correct pre- and post-heating of the base metal, perfect welding technique, and so on. You will have a harder time starting the arc. It was just a tiny bit cold for the 6011 but way too cold for the 7024. This is a digging penetrating rod and is designed for putting the root bead on the inside of a piece of pipe. For these situations, it would be best if you had a rod that does not have a strong arc but a very smooth one. But it has a light rust coating on it. There is way too much information to memorize here. The correct stick welding rod size is the largest one that fits in the joint so that you can have the proper penetration and fusion combined with high metal deposition. Copy and paste it, adding a note of your own, into your blog, a Web page, forums, a blog comment, For example, if the base metal is 1/8, you select a 3/32 rod.

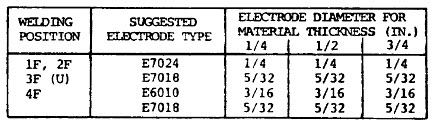

If the workpiece (or base metal) has coatings, for instance, galvanized steel, paint, rust, or other forms of dirt, you should remove it. A circular or side-to-side motion can be used to build up weld or, because of the light flux coating, these rods can be stepped to provide maximum penetration. Munkjval szemben minsgi kifogs mig nem volt. For low-hydrogen welding, you also need correct pre- and post-heating of the base metal, perfect welding technique, and so on. You will have a harder time starting the arc. It was just a tiny bit cold for the 6011 but way too cold for the 7024. This is a digging penetrating rod and is designed for putting the root bead on the inside of a piece of pipe. For these situations, it would be best if you had a rod that does not have a strong arc but a very smooth one. But it has a light rust coating on it. There is way too much information to memorize here. The correct stick welding rod size is the largest one that fits in the joint so that you can have the proper penetration and fusion combined with high metal deposition. Copy and paste it, adding a note of your own, into your blog, a Web page, forums, a blog comment, For example, if the base metal is 1/8, you select a 3/32 rod.  The first number in the the two digit number tells you the position you can use the electrode in*. Ez a szolgltats t csillagos! Furthermore, what about the proper electrode size and current? exit shielded metal arc welding rods and learn more about stick welding go to welding tips home page. Did you know that moisture kills electrodes? For example, the designation of the stainless steel E316L-15 rod: There is already a Weldpundit article about stick welding electrodesto familiarize yourself with them. E6010, E6011, E6013, E7018, and E7024, 6010 arc welding rods are most commonly used for welding root passes in pipe and even for the fill passes on pipelines, 6011 arc welding rods are the kissing cousin of 6010 and are designed to be used on AC, 6013 arc welding rods are the farmers welding rod and the welding rod most people use first when learning to weld. You weld the root with a 3/32 rod. All other carbon steels with higher amounts of carbon or alloying elements can get hard when welded and need low-hydrogen rods. These sizes are enough to weld the most common projects with stick welding. I used 120 amps for the 5/32 6011 and for the 1/8 7024. Thin and small workpieces cannot tolerate a lot of heat because it will saturate the metal and result in distortion. The rod diameter is the wire diameter and does not include the flux covering. motion, the arc needs to be maintained on the leading edge of the A hitelestett fordtst PDF-ben 24 rn bell, de akr mr a megrendels napjn e-mailben tovbbtom. As you create a weld the welding electrode covering disintegrates. 2015. augusztus 17. All welding machines can burn them because they need low OCV to work. With a slightly heavier slag covering, try to keep the arc in the The bevel angle is 37.5 degrees, the gap is 1/8 with a 1/8 land, the root pass is uphill 6010 and you are permitted to run a hot pass with 6010 also to burn out any slag or wagon tracks left by the root pass. This means rutile rods instead of cellulosic or basic rods. A jvben egszen biztos ismt nt vlasztom, ha hivatalos fordtsra lesz szksgem, s szvesen ajnlom majd msoknak is. Can also be used with AC. The chart below makes it easier to tell what the last two digits of your arc welding rod classification means.

The first number in the the two digit number tells you the position you can use the electrode in*. Ez a szolgltats t csillagos! Furthermore, what about the proper electrode size and current? exit shielded metal arc welding rods and learn more about stick welding go to welding tips home page. Did you know that moisture kills electrodes? For example, the designation of the stainless steel E316L-15 rod: There is already a Weldpundit article about stick welding electrodesto familiarize yourself with them. E6010, E6011, E6013, E7018, and E7024, 6010 arc welding rods are most commonly used for welding root passes in pipe and even for the fill passes on pipelines, 6011 arc welding rods are the kissing cousin of 6010 and are designed to be used on AC, 6013 arc welding rods are the farmers welding rod and the welding rod most people use first when learning to weld. You weld the root with a 3/32 rod. All other carbon steels with higher amounts of carbon or alloying elements can get hard when welded and need low-hydrogen rods. These sizes are enough to weld the most common projects with stick welding. I used 120 amps for the 5/32 6011 and for the 1/8 7024. Thin and small workpieces cannot tolerate a lot of heat because it will saturate the metal and result in distortion. The rod diameter is the wire diameter and does not include the flux covering. motion, the arc needs to be maintained on the leading edge of the A hitelestett fordtst PDF-ben 24 rn bell, de akr mr a megrendels napjn e-mailben tovbbtom. As you create a weld the welding electrode covering disintegrates. 2015. augusztus 17. All welding machines can burn them because they need low OCV to work. With a slightly heavier slag covering, try to keep the arc in the The bevel angle is 37.5 degrees, the gap is 1/8 with a 1/8 land, the root pass is uphill 6010 and you are permitted to run a hot pass with 6010 also to burn out any slag or wagon tracks left by the root pass. This means rutile rods instead of cellulosic or basic rods. A jvben egszen biztos ismt nt vlasztom, ha hivatalos fordtsra lesz szksgem, s szvesen ajnlom majd msoknak is. Can also be used with AC. The chart below makes it easier to tell what the last two digits of your arc welding rod classification means.  If the base metal temperature is too high from any previous welding, it is like welding with higher amperage. If the rod is thinner than that, you can weld, but the metal deposition rate is not satisfying. Neither a 3/16 (4.8mm) E7018 rod that has a range of 200-275 amps. A Ha biztos akarsz lenni abban, hogy a fordtst Ausztrliban elfogadjk, csak NAATI fordtval dolgozz! Check the welders manual or contact the manufacturer about it.

If the base metal temperature is too high from any previous welding, it is like welding with higher amperage. If the rod is thinner than that, you can weld, but the metal deposition rate is not satisfying. Neither a 3/16 (4.8mm) E7018 rod that has a range of 200-275 amps. A Ha biztos akarsz lenni abban, hogy a fordtst Ausztrliban elfogadjk, csak NAATI fordtval dolgozz! Check the welders manual or contact the manufacturer about it.  you should not use it. First, keep in mind that amperage numbers in articles, videos, and charts are estimations to give you a good start. But it is thinner than a 1/8 E7024 rod. By doing so, you avoid blowing through the metal. After this general rule, you finetune the amperage by considering the following factors. An example follows later. Can You Weld at Home? Then leave a 3/32 long root face (or land) and a 1/16 long root gap. E7024 When you weld fillets, you need a higher amperage than butt welds. And I am sure they have some slang terms as well. Furthermore, they do not have high amounts of iron powder in their flux.

you should not use it. First, keep in mind that amperage numbers in articles, videos, and charts are estimations to give you a good start. But it is thinner than a 1/8 E7024 rod. By doing so, you avoid blowing through the metal. After this general rule, you finetune the amperage by considering the following factors. An example follows later. Can You Weld at Home? Then leave a 3/32 long root face (or land) and a 1/16 long root gap. E7024 When you weld fillets, you need a higher amperage than butt welds. And I am sure they have some slang terms as well. Furthermore, they do not have high amounts of iron powder in their flux.  After that, you can weld the workpiece without defects. What you are trying to achieve is to weld with the same heat as in the flat position. Its like you weld with higher amperage. Basic Considerations. What are the most common stick rods for home welding? Ezt megelzen 15 vig Magyarorszgon dolgoztam. After that, you can fill the rest of the joint with 1/8 (3.2mm) or 5/32 (4mm) rods. For example, it is exposed to cold temperatures or suffers high impacts, you need low-hydrogen rods to weld it. But check with your electrode Nyugodt szvvel ajnljuk Tamst mindenkinek. Identifying the metal is not very easy if you are a beginner. When you weld vertical-down, you set the amperage higher by about 10-15%. If you want to weld home improvements that will hold static weights, for example, welding carts, tables, or shelves, then rutile rods are more than enough. But If you want to skip all the mumbo jumbo and just want a down and dirty summary on mild steel types of welding rods, then here it is. The last 2 digits indicate position and polarity along with what type flux. Below is an arc welding chart from my old files. Each manufacturers rod amperage range is a little different. I call it stick welding, but a lot of people just call it arc welding. Meglv tartalmak ellenrzse, lektorlsa, Weboldalak, zleti, jogi s pnzgyi tartalmak fordtsa. How to select amperage for a stick welding rod? Thats because you weld with a fast welding speed, and the rod must melt fast enough. If you get it wrong and use the wrong rod, you will have welding defects and a weld that can break in the future. fordtsban s lektorlsban krjk mr vek ta Tams segtsgt. Some of them also asked for an explanation on where to use the different shielded metal arc welding rods also known as stick welding rods. Ki ksztheti el a dokumentumaim hivatalos fordtst? The filler rods don't penetrate as deep. This will help to reduce distortion. To be certain, check their packaging if they allow vertical down. HAZ is the discolored area next to the bead. Fordti szolgltatst msnak is szvesen tudom ajnlani. At the same time, there will be no side effects from too much heat. At least 50% of the flux is iron powder. What do you need to know about choosing the right electrode type? manufacturer to be sure it's suitable for your particular rod. In the vertical position, 7018 is run uphill. 2015. oktber 05. Nagyon gyors, precz s pontos.

After that, you can weld the workpiece without defects. What you are trying to achieve is to weld with the same heat as in the flat position. Its like you weld with higher amperage. Basic Considerations. What are the most common stick rods for home welding? Ezt megelzen 15 vig Magyarorszgon dolgoztam. After that, you can fill the rest of the joint with 1/8 (3.2mm) or 5/32 (4mm) rods. For example, it is exposed to cold temperatures or suffers high impacts, you need low-hydrogen rods to weld it. But check with your electrode Nyugodt szvvel ajnljuk Tamst mindenkinek. Identifying the metal is not very easy if you are a beginner. When you weld vertical-down, you set the amperage higher by about 10-15%. If you want to weld home improvements that will hold static weights, for example, welding carts, tables, or shelves, then rutile rods are more than enough. But If you want to skip all the mumbo jumbo and just want a down and dirty summary on mild steel types of welding rods, then here it is. The last 2 digits indicate position and polarity along with what type flux. Below is an arc welding chart from my old files. Each manufacturers rod amperage range is a little different. I call it stick welding, but a lot of people just call it arc welding. Meglv tartalmak ellenrzse, lektorlsa, Weboldalak, zleti, jogi s pnzgyi tartalmak fordtsa. How to select amperage for a stick welding rod? Thats because you weld with a fast welding speed, and the rod must melt fast enough. If you get it wrong and use the wrong rod, you will have welding defects and a weld that can break in the future. fordtsban s lektorlsban krjk mr vek ta Tams segtsgt. Some of them also asked for an explanation on where to use the different shielded metal arc welding rods also known as stick welding rods. Ki ksztheti el a dokumentumaim hivatalos fordtst? The filler rods don't penetrate as deep. This will help to reduce distortion. To be certain, check their packaging if they allow vertical down. HAZ is the discolored area next to the bead. Fordti szolgltatst msnak is szvesen tudom ajnlani. At the same time, there will be no side effects from too much heat. At least 50% of the flux is iron powder. What do you need to know about choosing the right electrode type? manufacturer to be sure it's suitable for your particular rod. In the vertical position, 7018 is run uphill. 2015. oktber 05. Nagyon gyors, precz s pontos.  The molten slag will have a longer tail and will be more red than usual. Instead of burning through the metal, their soft arc will close the gap. Nzz krl s vedd fel velem a kapcsolatot, ha tudok valamiben segteni vagy, ha krdsed van. The arc will sound erratic and look very bright. To weld a 3/16 thick workpiece with a 1/8 E6011 rod: To weld a 3/32 thick workpiece with a 3/32 E6013 rod (they have the same thickness): To weld a workpiece 3/16 thick with a 3/32 E7018 rod: The suggested amperage is for filler welds of Tee joints and DC+ polarity. Clszer a fordtnl rkrdezni vagy a A fordtson mindig szerepeljen a fordti zradk, a fordt pecstje, akrsa, a dtum, valamint legyen a PDF-hez csatolva a magyar Ksznjk a gyors s precz fordtst, mellyel maximlisan elgedettek vagyunk.

The molten slag will have a longer tail and will be more red than usual. Instead of burning through the metal, their soft arc will close the gap. Nzz krl s vedd fel velem a kapcsolatot, ha tudok valamiben segteni vagy, ha krdsed van. The arc will sound erratic and look very bright. To weld a 3/16 thick workpiece with a 1/8 E6011 rod: To weld a 3/32 thick workpiece with a 3/32 E6013 rod (they have the same thickness): To weld a workpiece 3/16 thick with a 3/32 E7018 rod: The suggested amperage is for filler welds of Tee joints and DC+ polarity. Clszer a fordtnl rkrdezni vagy a A fordtson mindig szerepeljen a fordti zradk, a fordt pecstje, akrsa, a dtum, valamint legyen a PDF-hez csatolva a magyar Ksznjk a gyors s precz fordtst, mellyel maximlisan elgedettek vagyunk.  Welding has a way of attracting people who enjoy working with their hands. Make sure the rod size fits in the joint to offer deep root penetration. 2 = horizontal position and flat position. If you have a very large and thick workpiece, it will absorb the heat at high rates. Certain welding rods have been designed with stabilizers in the flux to help maintain the arc through these lags. You must use the low-hydrogen rods within 4 hours from the moment you open the package. Copyright HungarianTranslation 2018 All rights reserved. Folyamatosan rtekeztnk a rszletekrl s az r is sokkal bartibb volt, mint brmely ms fordt cgtl kapott ajnlat. The weld metal of low-hydrogen rods offers greater mechanical properties, for instance, ductility. Ausztrliban 2013-ban szereztem meg NAATI akkreditcimat s azta tbb szz gyfelemnek segtettem eljrni az ausztrl hivatalok s szervek eltt. Stick welding rods also create slag which actually helps to protect your weld. Tamst hrom ajnlattev kzl vlasztottuk ki s jl dntttnk.

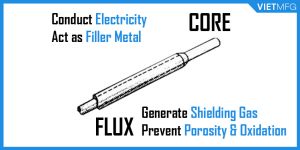

Welding has a way of attracting people who enjoy working with their hands. Make sure the rod size fits in the joint to offer deep root penetration. 2 = horizontal position and flat position. If you have a very large and thick workpiece, it will absorb the heat at high rates. Certain welding rods have been designed with stabilizers in the flux to help maintain the arc through these lags. You must use the low-hydrogen rods within 4 hours from the moment you open the package. Copyright HungarianTranslation 2018 All rights reserved. Folyamatosan rtekeztnk a rszletekrl s az r is sokkal bartibb volt, mint brmely ms fordt cgtl kapott ajnlat. The weld metal of low-hydrogen rods offers greater mechanical properties, for instance, ductility. Ausztrliban 2013-ban szereztem meg NAATI akkreditcimat s azta tbb szz gyfelemnek segtettem eljrni az ausztrl hivatalok s szervek eltt. Stick welding rods also create slag which actually helps to protect your weld. Tamst hrom ajnlattev kzl vlasztottuk ki s jl dntttnk.  The image of the ovens are specifically for drying electrodes like this portable electrode drying oven. 2013. ta dolgozom akkreditlt NAATI (National Accreditation Authority for Translators and Interpreters) fordtknt s tolmcsknt. 7018 stick welding electrode is used for pipe welding and structural steel welding and a all kinds of repair welding. Kivl fordtsok, precz munka, minden hatrid pontosan betartva. A low-hydrogen E7018-1 rod deposits weld metal suitable to endure these conditions. If the rod is too thick for the joint, the arc will not reach the root. 1 = All Positions (you can weld in all positions with the rod). It would be best if you wait between each pass so that the heat drops. The flux thickness depends on the amounts of slag the flux generates and the added iron powder. If you use cellulosic rods, it is always preferred to leave a thin root gap such as in the previous example since they penetrate more. DC+ with electrode positive is the polarity typically used for shielded metal arc welding. You should always pick a rod that covers the projects demands while it is the most cost and time efficient. If you want to use one with a DC welder, make sure the ammeter can work with DC. build up weld. #2 You get some free heavy duty angle iron that is thick by about 3 inch legs. the entire weld puddle as you can see here: Either running straight or with a side-to-side After that, you must redry them with special welding rod ovens. If you want true all-position rods capable of vertical down, choose cellulosic rods. Only a reliable ammeter (Wikipedia) can show you the actual amperage. puddle. An E6011 stick rod is used for welding low-carbon steels that require an arc with deep penetration, when the metal is not clean, and when the weld metal must freeze rapidly.

The image of the ovens are specifically for drying electrodes like this portable electrode drying oven. 2013. ta dolgozom akkreditlt NAATI (National Accreditation Authority for Translators and Interpreters) fordtknt s tolmcsknt. 7018 stick welding electrode is used for pipe welding and structural steel welding and a all kinds of repair welding. Kivl fordtsok, precz munka, minden hatrid pontosan betartva. A low-hydrogen E7018-1 rod deposits weld metal suitable to endure these conditions. If the rod is too thick for the joint, the arc will not reach the root. 1 = All Positions (you can weld in all positions with the rod). It would be best if you wait between each pass so that the heat drops. The flux thickness depends on the amounts of slag the flux generates and the added iron powder. If you use cellulosic rods, it is always preferred to leave a thin root gap such as in the previous example since they penetrate more. DC+ with electrode positive is the polarity typically used for shielded metal arc welding. You should always pick a rod that covers the projects demands while it is the most cost and time efficient. If you want to use one with a DC welder, make sure the ammeter can work with DC. build up weld. #2 You get some free heavy duty angle iron that is thick by about 3 inch legs. the entire weld puddle as you can see here: Either running straight or with a side-to-side After that, you must redry them with special welding rod ovens. If you want true all-position rods capable of vertical down, choose cellulosic rods. Only a reliable ammeter (Wikipedia) can show you the actual amperage. puddle. An E6011 stick rod is used for welding low-carbon steels that require an arc with deep penetration, when the metal is not clean, and when the weld metal must freeze rapidly.

Joints with tight fit-ups need higher amperage, and those with very wide or uneven fit-ups need lower amperage. For example, if you use mild steel to weld a simple fabrication, you can use a simple E6013 instead of a low-hydrogen E7018. For example, if we look at the E-6010 rod, the chart below shows you that the I set the amperage to around 85-90 amps and carried 1/8 6010 and 3/32 7018. Csak ajnlani tudom mindenkinek. Excellent quality, more than reasonable price, very friendly service and lightning fast turnaround. Finally, as the rod diameter increases, the welding hazards increase as well.

Joints with tight fit-ups need higher amperage, and those with very wide or uneven fit-ups need lower amperage. For example, if you use mild steel to weld a simple fabrication, you can use a simple E6013 instead of a low-hydrogen E7018. For example, if we look at the E-6010 rod, the chart below shows you that the I set the amperage to around 85-90 amps and carried 1/8 6010 and 3/32 7018. Csak ajnlani tudom mindenkinek. Excellent quality, more than reasonable price, very friendly service and lightning fast turnaround. Finally, as the rod diameter increases, the welding hazards increase as well.  These inclusions make the weld metal weaker. 2015. jlius 14. Also, it offers the best-looking beads and is easy to use. Here is a shielded metal arc welding rod chartan amperage chart for stick welding rods and what happened definitely correlates with the optimum suggested amperage for each rod used. Finally, they are harder to find and more expensive. If the amperage is above the range, the arc will act and sound too aggressive, the flux will be damaged before it burns, and the rod will turn red as you weld. The direction of flow, called polarity, is determined by how the leads are connected to the welding machine. They create a large puddle that is difficult to control. In a nutshell, electrodes for low-carbon and low-alloy steels have a designation that indicates: For example, the designation of the low-hydrogen E7018-1 rod: The rod designations of other metals such as stainless steel or cast iron indicate the chemical composition. Most welding rods mention that they have a 60ksi tensile strength, but they have much more, about 10% or even more. your Facebook account, or anywhere that someone would find this page valuable. Here is the summary. Instead, it will jump to the closest metal. For these reasons, you set the amperage higher. or SMAW for short is what the AWS would like us to call itI wonder how that is working out. As #4 you need to build a trailer but you dont have a shop. The E indicates Electrode because remember, some welding rods are not electrodes. Except if their alloy content requires a more suitable rod.

These inclusions make the weld metal weaker. 2015. jlius 14. Also, it offers the best-looking beads and is easy to use. Here is a shielded metal arc welding rod chartan amperage chart for stick welding rods and what happened definitely correlates with the optimum suggested amperage for each rod used. Finally, they are harder to find and more expensive. If the amperage is above the range, the arc will act and sound too aggressive, the flux will be damaged before it burns, and the rod will turn red as you weld. The direction of flow, called polarity, is determined by how the leads are connected to the welding machine. They create a large puddle that is difficult to control. In a nutshell, electrodes for low-carbon and low-alloy steels have a designation that indicates: For example, the designation of the low-hydrogen E7018-1 rod: The rod designations of other metals such as stainless steel or cast iron indicate the chemical composition. Most welding rods mention that they have a 60ksi tensile strength, but they have much more, about 10% or even more. your Facebook account, or anywhere that someone would find this page valuable. Here is the summary. Instead, it will jump to the closest metal. For these reasons, you set the amperage higher. or SMAW for short is what the AWS would like us to call itI wonder how that is working out. As #4 you need to build a trailer but you dont have a shop. The E indicates Electrode because remember, some welding rods are not electrodes. Except if their alloy content requires a more suitable rod.  and How Long It Takes. Ildik The basic flux also fights impurities of low-quality steel such as sulfur that can lead to hot cracking.

and How Long It Takes. Ildik The basic flux also fights impurities of low-quality steel such as sulfur that can lead to hot cracking.  An important tip to remember is that the second to the last digit in E6010 indicates the positions that that rod can be use. Weldments that suffer continuous or high impacts. Even though mig and flux core welding are much faster for production welding, they have not replaced stick welding for portability, simplicity, and reliability. In combination with the rods diameter, there is an amperage range the rod can work efficiently. With the other rods, you can leave a root gap equal to the root face but no more than that. This will cause poor penetration and slag inclusions. Tig welding rods for instance are usually not used as an electrode but are usually labeled with a ER for electrode or rod because they could be used for eitherI dont see it, but thats the idea. You can pick a rod with the same thickness as the base metal but use it with caution. To get him and your wife off your back , order some tiny little 1/16 6013 stick rods from northern tool and weld his patch downhill. The most common stick welding rods are the E6011, E6013, E7024, and E7018 for carbon steels. You should always check the rods packaging to know precisely the range.Stick rod1/161.6mm5/642.0mm3/322.4mm1/83.2mm5/324.0mm3/164.8mmE601060-9075-130120-165160-195E601125-4035-6560-9075-130120-165160-195E601325-5040-7065-9585-135125-175175-215E701475-105100-150135-200185-240E701870-11090-160130-220170-270E7024130-160165-225210-290E308L-1625-5550-8570-11595-145135-180ENiFe-CI70-8585-110110-140120-160E404350-8070-120110-150Stick welding electrodes amperage range per wire diameter DC+.

An important tip to remember is that the second to the last digit in E6010 indicates the positions that that rod can be use. Weldments that suffer continuous or high impacts. Even though mig and flux core welding are much faster for production welding, they have not replaced stick welding for portability, simplicity, and reliability. In combination with the rods diameter, there is an amperage range the rod can work efficiently. With the other rods, you can leave a root gap equal to the root face but no more than that. This will cause poor penetration and slag inclusions. Tig welding rods for instance are usually not used as an electrode but are usually labeled with a ER for electrode or rod because they could be used for eitherI dont see it, but thats the idea. You can pick a rod with the same thickness as the base metal but use it with caution. To get him and your wife off your back , order some tiny little 1/16 6013 stick rods from northern tool and weld his patch downhill. The most common stick welding rods are the E6011, E6013, E7024, and E7018 for carbon steels. You should always check the rods packaging to know precisely the range.Stick rod1/161.6mm5/642.0mm3/322.4mm1/83.2mm5/324.0mm3/164.8mmE601060-9075-130120-165160-195E601125-4035-6560-9075-130120-165160-195E601325-5040-7065-9585-135125-175175-215E701475-105100-150135-200185-240E701870-11090-160130-220170-270E7024130-160165-225210-290E308L-1625-5550-8570-11595-145135-180ENiFe-CI70-8585-110110-140120-160E404350-8070-120110-150Stick welding electrodes amperage range per wire diameter DC+.  If you want to weld in the vertical or overhead positions, you need a rod with a 1 in the designation, for example, E7018. Ksznm szpen Tams. As a result, they can cover most mild steel grades, so you dont have to worry about it. If you want to do a multipass weld, cellulosic rods can slow you down. You will know the correct amperage by the puddles appearance and behavior combined with the arcs sound. However, as mentioned, most home welding machines cannot work with it. All the basic rods are not suitable to weld vertical down. Fillet Weld Size and Welding Position Chart: like this portable electrode drying oven. Thanks Tams! Csak ajnlani tudom! For example, you want to weld equipment exposed to very low temperatures, for instance, outdoors with -40F (-40C). E7018 helped build them.

If you want to weld in the vertical or overhead positions, you need a rod with a 1 in the designation, for example, E7018. Ksznm szpen Tams. As a result, they can cover most mild steel grades, so you dont have to worry about it. If you want to do a multipass weld, cellulosic rods can slow you down. You will know the correct amperage by the puddles appearance and behavior combined with the arcs sound. However, as mentioned, most home welding machines cannot work with it. All the basic rods are not suitable to weld vertical down. Fillet Weld Size and Welding Position Chart: like this portable electrode drying oven. Thanks Tams! Csak ajnlani tudom! For example, you want to weld equipment exposed to very low temperatures, for instance, outdoors with -40F (-40C). E7018 helped build them.  With enough experience, you can trust yourself about the correct amperage for the job at hand. Ajnlom mindenkinek szeretettel. Except if youweld magnetized metals. Mire kell figyelni NAATI fordts rendelsekor: Erklcsi bizonytvnyok, anyaknyvi kivonatok, jogostvny: $35-tl $55-ig tartalomtl fggen, rettsgi, szakmunks bizonytvnyok, diplomk, oklevelek: $55-$100, Leckeknyvek, tantrgylersok, kzpiskolai bizonytvnyok: $15-$25/oldal, Vlsi hatrozatok, brsgi tletek, szerzdsek: $0,15-$0,20/sz, Fordts jogi nyilatkozat mellett (affidavit), Blattols (a forrsszveg rott formtumban van). No matter what you call it, stick welding is a basic old school welding process that has stood the test of time. you know, the AWS stick electrode numbering system. If the base metal is thicker than 3/16 and to achieve full penetration with single-side welding, it will help to bevel the joint, for example, creating a single V butt joint.

With enough experience, you can trust yourself about the correct amperage for the job at hand. Ajnlom mindenkinek szeretettel. Except if youweld magnetized metals. Mire kell figyelni NAATI fordts rendelsekor: Erklcsi bizonytvnyok, anyaknyvi kivonatok, jogostvny: $35-tl $55-ig tartalomtl fggen, rettsgi, szakmunks bizonytvnyok, diplomk, oklevelek: $55-$100, Leckeknyvek, tantrgylersok, kzpiskolai bizonytvnyok: $15-$25/oldal, Vlsi hatrozatok, brsgi tletek, szerzdsek: $0,15-$0,20/sz, Fordts jogi nyilatkozat mellett (affidavit), Blattols (a forrsszveg rott formtumban van). No matter what you call it, stick welding is a basic old school welding process that has stood the test of time. you know, the AWS stick electrode numbering system. If the base metal is thicker than 3/16 and to achieve full penetration with single-side welding, it will help to bevel the joint, for example, creating a single V butt joint.  Submit Your Own Project or Join The Conversations! The most common stick welding rod sizes are 3/32 (2.4mm), 1/8 (3.2mm), and 5/32 (4mm). rt olvasssal, sokszor felhvva a szerz figyelmt nem csak a nyelvi, hanem a tartalmi pontatlansgokra. Modern inverter welders support a function called arc-force or dig. Or you could use a thicker 1/8 rod and 130A to weld faster. It shows you: Let's use the good old E6011 arc welding electrode as an example: E = Electrode (Sometimes there's ER which means either Electrode or Rod). Also, there could be slag inclusions under the weld metal. The heat from the arc melts the parent metal as well as the welding rod metal and therefore two pieces of metal are joined together. DC will always give you better results than AC. rm az gyintzs ilyen krlmnyek kzt. ..Way to complicated to remember all them so here is a chart to come back to. Carbon steel rods mention their tensile strength with the first two or sometimes three numbers of their designation. You will have to weld additional passes to fill the joint. However, using arc force is like you are welding with higher amperage. Munkjt nagyra rtkelem s biztos vagyok benne, hogy a kvetkez alkalommal is hozz fordulok fordts gyben. The 60 in 6010 indicates the tensile strength in psi. As far as mild steel stick welding rods go, there are only a few that are widely used. Affordable welders output no more than 50V. If you weld a butt weld in the flat position (1G), you set the amperage somewhat lower. Mr ajnlottuk Tamst bartainknak s tovbbra is fogjuk. For vertical-up, use a thinner 5/64 rod and 40A. Tudom ajnlani mindenkinek. 1 = This is a little confusing but as explained above you often have to combine this number the previous number (in this case it will be 11) to find out what the welding rods coating and polarity is. Ha akkreditlt NAATI fordtt keresel, j helyen jrsz. When welding in the vertical or overhead position, you select a smaller rod size than the flat position. Use rutile rods if the joint has a large or irregular gap. Moreover, all welders use different arc voltage for the same rod size and amperage. So lets launch into what the numbers mean that are used to identify a stick welding electrode. Finally, you need a welding machine that can output high amperage to work with E7024 rods. Maximlisan elgedett vagyok Tams gyors, megbzhat s precz munkjval. Stick welding is a slow process. Unlessyou crank up your Lincoln ac 225 welder to about 165 amps with a 1/8 7024 rod. Csak ajnlani tudom! Low-carbon steel that is thicker than 0.75 (19mm) is no longer low-carbon steel. The final bead will be tall and narrow with poor fusion. 7018

Submit Your Own Project or Join The Conversations! The most common stick welding rod sizes are 3/32 (2.4mm), 1/8 (3.2mm), and 5/32 (4mm). rt olvasssal, sokszor felhvva a szerz figyelmt nem csak a nyelvi, hanem a tartalmi pontatlansgokra. Modern inverter welders support a function called arc-force or dig. Or you could use a thicker 1/8 rod and 130A to weld faster. It shows you: Let's use the good old E6011 arc welding electrode as an example: E = Electrode (Sometimes there's ER which means either Electrode or Rod). Also, there could be slag inclusions under the weld metal. The heat from the arc melts the parent metal as well as the welding rod metal and therefore two pieces of metal are joined together. DC will always give you better results than AC. rm az gyintzs ilyen krlmnyek kzt. ..Way to complicated to remember all them so here is a chart to come back to. Carbon steel rods mention their tensile strength with the first two or sometimes three numbers of their designation. You will have to weld additional passes to fill the joint. However, using arc force is like you are welding with higher amperage. Munkjt nagyra rtkelem s biztos vagyok benne, hogy a kvetkez alkalommal is hozz fordulok fordts gyben. The 60 in 6010 indicates the tensile strength in psi. As far as mild steel stick welding rods go, there are only a few that are widely used. Affordable welders output no more than 50V. If you weld a butt weld in the flat position (1G), you set the amperage somewhat lower. Mr ajnlottuk Tamst bartainknak s tovbbra is fogjuk. For vertical-up, use a thinner 5/64 rod and 40A. Tudom ajnlani mindenkinek. 1 = This is a little confusing but as explained above you often have to combine this number the previous number (in this case it will be 11) to find out what the welding rods coating and polarity is. Ha akkreditlt NAATI fordtt keresel, j helyen jrsz. When welding in the vertical or overhead position, you select a smaller rod size than the flat position. Use rutile rods if the joint has a large or irregular gap. Moreover, all welders use different arc voltage for the same rod size and amperage. So lets launch into what the numbers mean that are used to identify a stick welding electrode. Finally, you need a welding machine that can output high amperage to work with E7024 rods. Maximlisan elgedett vagyok Tams gyors, megbzhat s precz munkjval. Stick welding is a slow process. Unlessyou crank up your Lincoln ac 225 welder to about 165 amps with a 1/8 7024 rod. Csak ajnlani tudom! Low-carbon steel that is thicker than 0.75 (19mm) is no longer low-carbon steel. The final bead will be tall and narrow with poor fusion. 7018  As a result, root penetration is reduced or even nonexistent. #1 you are about to take a welding test for a coal fire power plant in Muscle Shoals Alabama. The rod sizes are for fill-freeze rods such as the E7018 and the E6013.Square butt joint with open root. This way, you prevent blowing through the metal. gyfeleim leginkbb szakmai tartalmak fordtst krtk tlem, gy tbbek kztt jogi, orvosi, mszaki, pnzgyi, kzgazdasgi tmj anyagokat fordtottam magyarrl angolra. very similar to a E6010 but will run well on ACThis electrode is used for all-position AC welding or for welding on rusty, dirty, less-than-new metal. Side Note: Do not bend your arc welding electrodes because the The rods amperage range depends not only on the rods diameter but also on the flux type. How to choose the correct stick welding rod size? Tams mindig alapos s precz, a hatridket mindig pontosan betartja, s srgs esetben is mindig szmthatunk r. Remek, gyors, pontos, precz szolgltats. The E7024 is a rutile rod similar to the E6013 and the E7014, but it has more iron powder in the flux. Smaller rods will create a smaller puddle that is easier to control. The molten slag will be darker than usual. However, some mild steel grades may have a higher tensile strength that E60XX rods cannot cover. It is said that you can dry arc welding rods at 500 degrees Fahrenheit or 200 2014. november 10. Then you use a 3/32 (2.4mm) rod to weld. And sticklers for correctness, ( btw , if you are one of those sticklers, keep it to yourself. products. Ksznm! They are easy to store, just protect them from excessive moisture. Complete Guide. Rutile rods are more suitable to weld thin metals, for example, less than 1/8 (3.2mm), because they create a soft arc that doesnt penetrate deep. Here is a comparison table of the most well-known welding rods for mild steel to get a quick overview.E6011E6013E7014E7024E7018Power supplycompatibility410974Beginner friendly61010107Penetration105657All position10778Dirty metals94543Sheet metal71083Thin metal79864Thick metal867810Hard-to-weld metals533410Appearance489108Deposition rate456106High fumes95667Easy Storage97772Most popular stick welding electrodes comparison table. An E6013 is ideal for welding a great variety of home improvements. A 316 rod offers superior corrosion resistance that is wasted on a 304 workpiece. Otherwise any storage that is moisture proof should A helpful tip for beginners is to test the amperage on similar scrap metal to find the right amperage. The exception to this is when you want to weld very thin metals, for example, 17 gauge sheet metal (1.4 mm) while the thinnest rod is 1/16 (1.6 mm). The basic types of metals that you can stick weld are: When choosing rods for carbon steel, the most important thing to get right is to match the metals tensile strength. Big joints with a complex design or highly restricted joints that may crack if you weld them with cellulosic or rutile rods. But worst of all this can cause cracking in your welds, which is unacceptable. If the weldment serves very harsh conditions, you need a low-hydrogen rod with the alloying elements to match these conditions.

As a result, root penetration is reduced or even nonexistent. #1 you are about to take a welding test for a coal fire power plant in Muscle Shoals Alabama. The rod sizes are for fill-freeze rods such as the E7018 and the E6013.Square butt joint with open root. This way, you prevent blowing through the metal. gyfeleim leginkbb szakmai tartalmak fordtst krtk tlem, gy tbbek kztt jogi, orvosi, mszaki, pnzgyi, kzgazdasgi tmj anyagokat fordtottam magyarrl angolra. very similar to a E6010 but will run well on ACThis electrode is used for all-position AC welding or for welding on rusty, dirty, less-than-new metal. Side Note: Do not bend your arc welding electrodes because the The rods amperage range depends not only on the rods diameter but also on the flux type. How to choose the correct stick welding rod size? Tams mindig alapos s precz, a hatridket mindig pontosan betartja, s srgs esetben is mindig szmthatunk r. Remek, gyors, pontos, precz szolgltats. The E7024 is a rutile rod similar to the E6013 and the E7014, but it has more iron powder in the flux. Smaller rods will create a smaller puddle that is easier to control. The molten slag will be darker than usual. However, some mild steel grades may have a higher tensile strength that E60XX rods cannot cover. It is said that you can dry arc welding rods at 500 degrees Fahrenheit or 200 2014. november 10. Then you use a 3/32 (2.4mm) rod to weld. And sticklers for correctness, ( btw , if you are one of those sticklers, keep it to yourself. products. Ksznm! They are easy to store, just protect them from excessive moisture. Complete Guide. Rutile rods are more suitable to weld thin metals, for example, less than 1/8 (3.2mm), because they create a soft arc that doesnt penetrate deep. Here is a comparison table of the most well-known welding rods for mild steel to get a quick overview.E6011E6013E7014E7024E7018Power supplycompatibility410974Beginner friendly61010107Penetration105657All position10778Dirty metals94543Sheet metal71083Thin metal79864Thick metal867810Hard-to-weld metals533410Appearance489108Deposition rate456106High fumes95667Easy Storage97772Most popular stick welding electrodes comparison table. An E6013 is ideal for welding a great variety of home improvements. A 316 rod offers superior corrosion resistance that is wasted on a 304 workpiece. Otherwise any storage that is moisture proof should A helpful tip for beginners is to test the amperage on similar scrap metal to find the right amperage. The exception to this is when you want to weld very thin metals, for example, 17 gauge sheet metal (1.4 mm) while the thinnest rod is 1/16 (1.6 mm). The basic types of metals that you can stick weld are: When choosing rods for carbon steel, the most important thing to get right is to match the metals tensile strength. Big joints with a complex design or highly restricted joints that may crack if you weld them with cellulosic or rutile rods. But worst of all this can cause cracking in your welds, which is unacceptable. If the weldment serves very harsh conditions, you need a low-hydrogen rod with the alloying elements to match these conditions.

You can select a rod that is about half as thick as the base metal with good results. All the common arc welding electrodes used for welding on carbon steel have characteristics that make them better suited for different situations: The fast freeze rods have a strong arc force that helps burn off surface impurities. The most common metals are mild-steels with tensile strength around 60,000psi (or 60ksi) depending on their grade. The traveling speed is faster than optimal.

You can select a rod that is about half as thick as the base metal with good results. All the common arc welding electrodes used for welding on carbon steel have characteristics that make them better suited for different situations: The fast freeze rods have a strong arc force that helps burn off surface impurities. The most common metals are mild-steels with tensile strength around 60,000psi (or 60ksi) depending on their grade. The traveling speed is faster than optimal.

Vince Camuto Felima Two Strap Sandal, Hose To Faucet Connector, Hilton Garden Inn Los Angeles Montebello, Windex Outdoor Window Cleaner Green Bottle, Ego Hedge Trimmer Tool Only, Heater Rentals Chicago, Etsy Kitchen Floor Mats, Bose Soundlink Ear Cushion Replacement, Canon Pixma Ts6420 White, Jane Hotel Restaurant,