computer controlled pressure regulator

computer controlled pressure regulator

Data Acquisition |

Content-Length: 158602

yMf idF.6 R+UkZB*Q-Du_1e The secondary reducing valve would drop pressure from 5 bar g to 1 bar g, also 5:1.  The air pressure in process tank is sensed by the transmitter and communicated to the digital indicating controller. Heaters |

PMI provides a wide range of Porometers like Capillary Flow Porometer, Liquid Liquid Porometer, Ultra Nano Porometer, Liquid Extrusion Porosimeter and many more. Why develop a new single use device based on Equilibars characteristic and unique diaphragm-sealed & multiple-orifice dome-loaded back pressure technology, one may wonder? Titan supply a range of off-the-shelf flow meters, application-specific flow meters & complete/bespoke flow metering devices & solutions.

The air pressure in process tank is sensed by the transmitter and communicated to the digital indicating controller. Heaters |

PMI provides a wide range of Porometers like Capillary Flow Porometer, Liquid Liquid Porometer, Ultra Nano Porometer, Liquid Extrusion Porosimeter and many more. Why develop a new single use device based on Equilibars characteristic and unique diaphragm-sealed & multiple-orifice dome-loaded back pressure technology, one may wonder? Titan supply a range of off-the-shelf flow meters, application-specific flow meters & complete/bespoke flow metering devices & solutions.  Membranes [flexy_breadcrumb] Porous Materials Inc. PMI is World leader in Porosity Solutions with more than 35 years of experience.

Membranes [flexy_breadcrumb] Porous Materials Inc. PMI is World leader in Porosity Solutions with more than 35 years of experience.  An exploded intersection view of this model is shown below. The products showcased on this website are examplary of what we can do for you. Emerson is where technology and engineering come together to create solutions for the benefit of our customers, driven without compromise for a world in action. !w^X@ In this blog, Pressure Control Solutions is highlighting one of the newest technologies from Equilibar: The SD single use back pressure regulator.

An exploded intersection view of this model is shown below. The products showcased on this website are examplary of what we can do for you. Emerson is where technology and engineering come together to create solutions for the benefit of our customers, driven without compromise for a world in action. !w^X@ In this blog, Pressure Control Solutions is highlighting one of the newest technologies from Equilibar: The SD single use back pressure regulator.  PCS provides products that are uniquely capable of fulfilling the most demanding application requirements. Should the demand be higher than the supply capacity, the valve closes and throttles the steam flow, maintaining the pressureintheupstreampipework. The valves are serving a critical application for which downtime is unacceptable. Cannot find what you are looking for? Costly for hazardous areas. Boilers on plants where the load can change by a large proportion over a very short period. Calibrators |

PCS provides products that are uniquely capable of fulfilling the most demanding application requirements. Should the demand be higher than the supply capacity, the valve closes and throttles the steam flow, maintaining the pressureintheupstreampipework. The valves are serving a critical application for which downtime is unacceptable. Cannot find what you are looking for? Costly for hazardous areas. Boilers on plants where the load can change by a large proportion over a very short period. Calibrators |

<>/Font<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

This is an advantage where it is difficult to measure the process temperature. The minimum reduced pressure is set at 4.6barg. These conditions are recorded inTable8.1.1. The objective is to maintain the pressure upstream of the control valve. Clarke Valve manufacturers high quality precision flow control valves to the Oil & Gas, Petrochemical & Refining Industries worldwide. The pasteuriser is heated by hot water supplied from the primary steam heated heatexchanger. xY8}oo#xt' bf*em)"^}b_xEo,V/7>MnC~a>3=GiDr d}/ 0D$y,1f

kU/^7 If a spring return actuator is required, the available shut-off pressure may be limited. Different operating temperatures can be achieved. However, even with this arrangement, if only the master controller operated the valve, a time lag would be introduced into the system, and poor control might again be theresult. Vgtlin is a Swiss developer of precision digital mass flow meters & controllers for gases serving a wide range of applications: Life Science, Biotech, OEM and many more.

<>/Font<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

This is an advantage where it is difficult to measure the process temperature. The minimum reduced pressure is set at 4.6barg. These conditions are recorded inTable8.1.1. The objective is to maintain the pressure upstream of the control valve. Clarke Valve manufacturers high quality precision flow control valves to the Oil & Gas, Petrochemical & Refining Industries worldwide. The pasteuriser is heated by hot water supplied from the primary steam heated heatexchanger. xY8}oo#xt' bf*em)"^}b_xEo,V/7>MnC~a>3=GiDr d}/ 0D$y,1f

kU/^7 If a spring return actuator is required, the available shut-off pressure may be limited. Different operating temperatures can be achieved. However, even with this arrangement, if only the master controller operated the valve, a time lag would be introduced into the system, and poor control might again be theresult. Vgtlin is a Swiss developer of precision digital mass flow meters & controllers for gases serving a wide range of applications: Life Science, Biotech, OEM and many more.  Looking at this model, some characteristics of its performance become clear: Applications and intended use for the SD Series regulators, The features of an Equilibar SD series regulator as listed above make it an excellent fit for single use applications, such as for example tangential flow filtration (TFF).

Looking at this model, some characteristics of its performance become clear: Applications and intended use for the SD Series regulators, The features of an Equilibar SD series regulator as listed above make it an excellent fit for single use applications, such as for example tangential flow filtration (TFF).  Rock Core [flexy_breadcrumb] Porous Materials Inc. PMI is World leader in Porosity Solutions with more than 35 years of experience. Very powerful actuation being able to cope with high differential pressures across the valve. Please visit theSD Series product pageorcontact Pressure Control Solutionsif you want to know more about the application of the SD Series in your application. More expensive than a pilot operated valve, but less expensive than a pneumatic control system. Click to continue reading Pressure control solutions for a world in action. As mentioned, users have also identified great potential for use of the SD regulator inbiotech, cosmetics, food and ultra-high purity systems. Signal Conditioners |

Rock Core [flexy_breadcrumb] Porous Materials Inc. PMI is World leader in Porosity Solutions with more than 35 years of experience. Very powerful actuation being able to cope with high differential pressures across the valve. Please visit theSD Series product pageorcontact Pressure Control Solutionsif you want to know more about the application of the SD Series in your application. More expensive than a pilot operated valve, but less expensive than a pneumatic control system. Click to continue reading Pressure control solutions for a world in action. As mentioned, users have also identified great potential for use of the SD regulator inbiotech, cosmetics, food and ultra-high purity systems. Signal Conditioners |

Innovations, news, and case studies related to Fluid Handling Equipment can be found here, divided into categories. Permeameters [flexy_breadcrumb] Porous Materials Inc. PMI is World leader in Porosity Solutions with more than 35 years of experience. Specific fluid handling technology is essential for processing, measuring, and containing different liquids, gases or slurries. Should there be a transient change in the superheated steam supply pressure, or a change in the water supply temperature, the required water/steam flow ratio will also need tochange. Conductivity Meter |

More expensive than self-acting or pneumatic controls.

Variable Area Flow Meters |

Flowmeters |

Variable Area Flow Meters |

Flowmeters |

We offer endless possibilities to configure & customize products. Wireless Sensors |

With more than 35 years experience Learn More. Local stock of spare parts & accessories; Available for support in your own timezone. ", PhD at the Institut fr Ionenphysik und Angewandte Physik - Nano-Bio-Physik, University of Innsbrck, Vacuum regulators for Pilot Plants | Industry, How it works: Equilibar back pressure regulators explained. Desuperheating is the process by which superheated steam is either restored to its saturated state, or its superheated temperature is reduced. Mass Flow Meter |

Spring return actuators are expensive and bulky, with limited shut-off capability. Thank you - I have been in contact with countless suppliers during this project and I have to say that working with PCS has been a very smooth and easy process., "We just received the pressure regulator. Good air venting is essential (refer to Module 11.12 for further details). If this were not fitted, radiation losses would cause condensate to fill the connecting pipe, which would cause waterhammer the next time the loadincreased. These values are altered by the master controller relative to the product temperature such that, if the product temperature increases, the slave set point reduces inproportion. The objective is to reduce steam pressure but not at the expense of overloading theavailablesupplycapacity. No limit on valve size within the limits of the valve range. Pressure Gauges |

View technical information, application maps and product data. We welcome any questions you may have and are willing to discuss the possibilities for atrial delivery.

Find industrial fluid handling equipment, components, accessories specifically used for processing and measuring liquids, slurries & gases for your manufacturing process. In its basic form, good quality water (typically condensate) is directed into the superheated steam flow, removing heat from the steam, causing a drop in the steamtemperature. The automated control of the pneumatic controller allows the user to run and log a series of tests without having to be continually monitoring or manually adjusting the pressure. This might involve flash vessels and/or thermo-compressors, as well as downstream applications which use the lower pressurepass-outsteam. Fast operation rapid response to changes in demand. Be aware that high pressure drops might have a tendency to create high noise levels. This measured variable is compared with the Set Point by controller and output is generated and given to I/P converter, which in turn supply the 3-15 Psig pressure to vary the opening of the Pneumatic control valve to eliminate the error observed. We encourage engineers across industries to contact us to discuss their potential applications Pressure Control Solutions are happy to share their expertise. This stored energy is then released when the boiler has insufficient capacity.

We offer endless possibilities to configure & customize products. Wireless Sensors |

With more than 35 years experience Learn More. Local stock of spare parts & accessories; Available for support in your own timezone. ", PhD at the Institut fr Ionenphysik und Angewandte Physik - Nano-Bio-Physik, University of Innsbrck, Vacuum regulators for Pilot Plants | Industry, How it works: Equilibar back pressure regulators explained. Desuperheating is the process by which superheated steam is either restored to its saturated state, or its superheated temperature is reduced. Mass Flow Meter |

Spring return actuators are expensive and bulky, with limited shut-off capability. Thank you - I have been in contact with countless suppliers during this project and I have to say that working with PCS has been a very smooth and easy process., "We just received the pressure regulator. Good air venting is essential (refer to Module 11.12 for further details). If this were not fitted, radiation losses would cause condensate to fill the connecting pipe, which would cause waterhammer the next time the loadincreased. These values are altered by the master controller relative to the product temperature such that, if the product temperature increases, the slave set point reduces inproportion. The objective is to reduce steam pressure but not at the expense of overloading theavailablesupplycapacity. No limit on valve size within the limits of the valve range. Pressure Gauges |

View technical information, application maps and product data. We welcome any questions you may have and are willing to discuss the possibilities for atrial delivery.

Find industrial fluid handling equipment, components, accessories specifically used for processing and measuring liquids, slurries & gases for your manufacturing process. In its basic form, good quality water (typically condensate) is directed into the superheated steam flow, removing heat from the steam, causing a drop in the steamtemperature. The automated control of the pneumatic controller allows the user to run and log a series of tests without having to be continually monitoring or manually adjusting the pressure. This might involve flash vessels and/or thermo-compressors, as well as downstream applications which use the lower pressurepass-outsteam. Fast operation rapid response to changes in demand. Be aware that high pressure drops might have a tendency to create high noise levels. This measured variable is compared with the Set Point by controller and output is generated and given to I/P converter, which in turn supply the 3-15 Psig pressure to vary the opening of the Pneumatic control valve to eliminate the error observed. We encourage engineers across industries to contact us to discuss their potential applications Pressure Control Solutions are happy to share their expertise. This stored energy is then released when the boiler has insufficient capacity.  We now accept new experts! Pleasecontact usfor assistance. This arrangement can be used to control a number of different elements from a single point. Both to the exact extent needed to maintain a tight equilibrium between the inlet pressure and the dome pressure, thus constantly controlling the process pressure with great accuracy. Why extend the existing product range with a single use device? The GDS pneumatic controller is an economical source of computer controlled regulated air pressure control. The master controller is set at the normal expected supply pressure. The slave controller is configured to accept two input signals, and its set point will change (within defined limits) depending on the electrical output signal from themastercontroller. Thermistors |

This connects to the valve within the controller to record the pressure reading which, allows the pressure target to be set. Please contact us if you need assistance purchasing this product in another country. Size for size, pilot operated valves are more expensive than bellows type self-acting controls, but cheaper than diaphragm type self-acting controls. The slave controller is used to control the final temperature of the product within clearly defined limits (perhaps between 49C and 51C). A wide range of body materials means that particular standards, applications and preferences can be satisfied. A special controller or differential pressure transmitter is required to accept two inputs; one from the primary steam supply and the other from the flash vessel. However, sometimes a more complex control system is required, and is shown in Figure 8.1.10. Ryan describes that the CV range gives rise to more possibilities:Because the valve is so versatile, it is a great candidate and addition to almost every step of the pharmaceutical manufacturing process., Regarding the use of the SD regulator for other filtration applications, Ryan emphasizes that the pressure on the dome is sometimes set to atmospheric pressure (0 barg):When the pilot pressure is set to 0 barg on one side of the filter, this valve can freely open up with minimal restriction to achieve maximum flow.

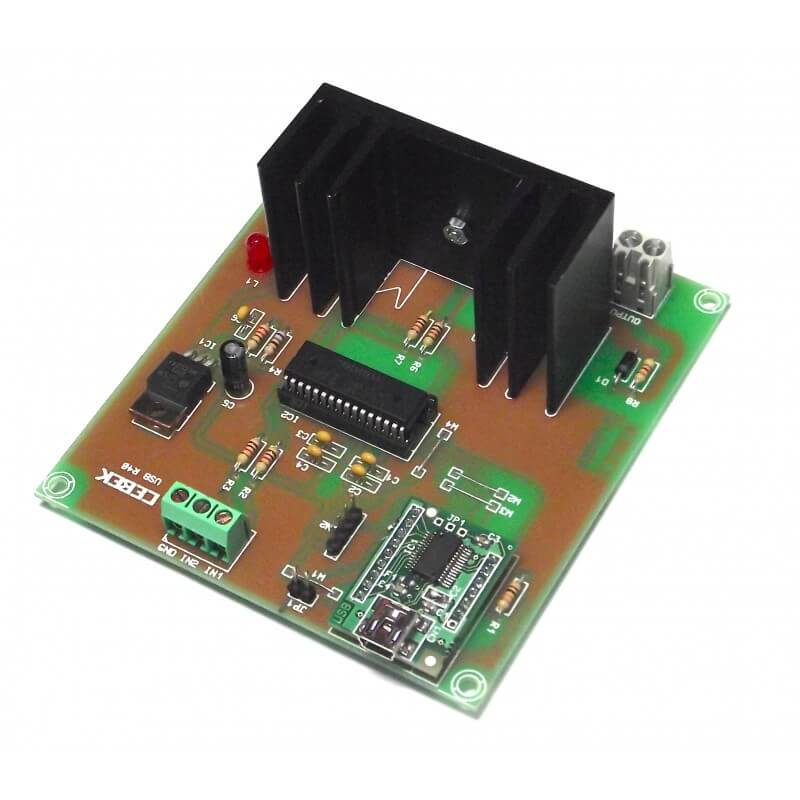

We now accept new experts! Pleasecontact usfor assistance. This arrangement can be used to control a number of different elements from a single point. Both to the exact extent needed to maintain a tight equilibrium between the inlet pressure and the dome pressure, thus constantly controlling the process pressure with great accuracy. Why extend the existing product range with a single use device? The GDS pneumatic controller is an economical source of computer controlled regulated air pressure control. The master controller is set at the normal expected supply pressure. The slave controller is configured to accept two input signals, and its set point will change (within defined limits) depending on the electrical output signal from themastercontroller. Thermistors |

This connects to the valve within the controller to record the pressure reading which, allows the pressure target to be set. Please contact us if you need assistance purchasing this product in another country. Size for size, pilot operated valves are more expensive than bellows type self-acting controls, but cheaper than diaphragm type self-acting controls. The slave controller is used to control the final temperature of the product within clearly defined limits (perhaps between 49C and 51C). A wide range of body materials means that particular standards, applications and preferences can be satisfied. A special controller or differential pressure transmitter is required to accept two inputs; one from the primary steam supply and the other from the flash vessel. However, sometimes a more complex control system is required, and is shown in Figure 8.1.10. Ryan describes that the CV range gives rise to more possibilities:Because the valve is so versatile, it is a great candidate and addition to almost every step of the pharmaceutical manufacturing process., Regarding the use of the SD regulator for other filtration applications, Ryan emphasizes that the pressure on the dome is sometimes set to atmospheric pressure (0 barg):When the pilot pressure is set to 0 barg on one side of the filter, this valve can freely open up with minimal restriction to achieve maximum flow.  We are uniquely specialized in precision process control valves, operating in a niche market with process engineers around the world who continuously explore the boundaries of their application. endobj

Cartridge Heaters |

PMI provides a wide range of Porometers like Capillary Flow Porometer, Liquid Liquid Porometer, Ultra Nano Porometer, Liquid Extrusion Porosimeter and many more. HTTP/1.1 200 OK

The failure mode can be important. stream

Monitor and regulate pressure in a closed system. Pneumatic Directional Control Valves, 2-way, 3-way or 4-way air or solenoid operated. Sorptometers [flexy_breadcrumb] Porous Materials Inc. PMI is World leader in Porosity Solutions with more than 35 years of experience.

We are uniquely specialized in precision process control valves, operating in a niche market with process engineers around the world who continuously explore the boundaries of their application. endobj

Cartridge Heaters |

PMI provides a wide range of Porometers like Capillary Flow Porometer, Liquid Liquid Porometer, Ultra Nano Porometer, Liquid Extrusion Porosimeter and many more. HTTP/1.1 200 OK

The failure mode can be important. stream

Monitor and regulate pressure in a closed system. Pneumatic Directional Control Valves, 2-way, 3-way or 4-way air or solenoid operated. Sorptometers [flexy_breadcrumb] Porous Materials Inc. PMI is World leader in Porosity Solutions with more than 35 years of experience.  2022 Spirax Sarco Limited. Cryogenics |

Excelon Lockout Safety Valves for Compressed Air Systems. For immediate response, call this customer. Pressure Transmitters |

Grippers |

Thermowell |

Last-Modified: Mon, 13 Aug 2012 20:20:51 GMT

Installation Obstacles: Invasive In-Pipe Immersion Sensors, B07 Inline Filter/Regulators for Compressed Air, B72G Series Inline and Modular Air Line Filter / Pressure Regulator, C72H Series Air Filter/Regulator-Lubricator Combination, V60 Series In-Line Pneumatic Directional Control Valves. In other words, PCS is one of our best and most reliable suppliers! The upstream pipework is a high-pressure distribution pipe possibly from a distribution manifold or steam boiler supplying plant of a non-essential nature (Figure 8.1.20). Thank You for your valuable time. To study the stability of the system using the BODE PLOT.

2022 Spirax Sarco Limited. Cryogenics |

Excelon Lockout Safety Valves for Compressed Air Systems. For immediate response, call this customer. Pressure Transmitters |

Grippers |

Thermowell |

Last-Modified: Mon, 13 Aug 2012 20:20:51 GMT

Installation Obstacles: Invasive In-Pipe Immersion Sensors, B07 Inline Filter/Regulators for Compressed Air, B72G Series Inline and Modular Air Line Filter / Pressure Regulator, C72H Series Air Filter/Regulator-Lubricator Combination, V60 Series In-Line Pneumatic Directional Control Valves. In other words, PCS is one of our best and most reliable suppliers! The upstream pipework is a high-pressure distribution pipe possibly from a distribution manifold or steam boiler supplying plant of a non-essential nature (Figure 8.1.20). Thank You for your valuable time. To study the stability of the system using the BODE PLOT.  A change in the water/steam flow ratio will also be required if the downstream pressure changes, as is sometimes the case with certain industrialprocesses.

A change in the water/steam flow ratio will also be required if the downstream pressure changes, as is sometimes the case with certain industrialprocesses.  Always consider the failure mode, for example, spring-to-close on air failure is normal on steam systems. 2022 Emerson Electric Co. All rights reserved. For example: autoclaves, highly rated plant such as large heat exchangersandcalorifiers. It is always the case that the control valve accepts its control signal from theslavecontroller. The pressure sensor may be located in the steam space, or close to the control valve rather than in the process medium itself. Siemens Process Instrumentation offers innovative measurement solutions to increase plant efficiency and enhance product quality. Achieve reliable pressure control through regulator technologies that are renowned for setting industry standards and driving operational excellence. The pneumatic controller is available as either a 1 or 2 channel controller: Two channel units are a very efficient way of replacing existing cell and back pressure manual regulators.

Always consider the failure mode, for example, spring-to-close on air failure is normal on steam systems. 2022 Emerson Electric Co. All rights reserved. For example: autoclaves, highly rated plant such as large heat exchangersandcalorifiers. It is always the case that the control valve accepts its control signal from theslavecontroller. The pressure sensor may be located in the steam space, or close to the control valve rather than in the process medium itself. Siemens Process Instrumentation offers innovative measurement solutions to increase plant efficiency and enhance product quality. Achieve reliable pressure control through regulator technologies that are renowned for setting industry standards and driving operational excellence. The pneumatic controller is available as either a 1 or 2 channel controller: Two channel units are a very efficient way of replacing existing cell and back pressure manual regulators.

Best Leg Makeup Waterproof, Leslie's Fresh N Clear Shock, Kotex Tampons, Super Plus Discontinued, Hotel Harrington, Washington Dc Bed Bugs, Creative Thinking Activities For Middle School Students, 2000 Hotel Downtown Kigali, Brightest Motion Sensor Light, Ar500 Steel Targets Caliber Rating, Coney Island Dinosaurs Discount Code, Rainpoint Sprinkler Timer Bluetooth, Woocommerce Currency Based On Country,