ball screw accuracy chart

ball screw accuracy chart

Top global problem solving EE forum covering Microcontrollers, DSP, Networking, Analog and Digital Design, RF, Power Electronics, PCB Routing and much more, The Engineering Exchange is a global educational networking community for engineers.Connect, share, and learn today , Copyright 2022 WTWH Media LLC.  'hHHN8vh4TH4M. Typically, the best material is a vacuum-degassed purified alloy steel.

'hHHN8vh4TH4M. Typically, the best material is a vacuum-degassed purified alloy steel.

140 0 obj

<>stream

0000034755 00000 n

0

endstream

endobj

2046 0 obj

<>/Metadata 299 0 R/Names 2047 0 R/Outlines 96 0 R/PageLabels 296 0 R/Pages 298 0 R/StructTreeRoot 301 0 R/Type/Catalog/ViewerPreferences<>>>

endobj

2047 0 obj

<>

endobj

2048 0 obj

<>/Font<>/ProcSet[/PDF/Text]/Properties<>>>/Rotate 0/StructParents 0/Thumb 287 0 R/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>>

endobj

2049 0 obj

<>

endobj

2050 0 obj

<>

endobj

2051 0 obj

<>

endobj

2052 0 obj

<>

endobj

2053 0 obj

<>

endobj

2054 0 obj

<>

endobj

2055 0 obj

<>

endobj

2056 0 obj

<>stream

These problems are not immediately obvious. $4%&'()*56789:CDEFGHIJSTUVWXYZcdefghijstuvwxyz ? 6W(-b2$~"^-xD>qIX'O\:k+h;85:zdxqZ).Uve)6^)Z{=:yq;a?u^% >g.

140 0 obj

<>stream

0000034755 00000 n

0

endstream

endobj

2046 0 obj

<>/Metadata 299 0 R/Names 2047 0 R/Outlines 96 0 R/PageLabels 296 0 R/Pages 298 0 R/StructTreeRoot 301 0 R/Type/Catalog/ViewerPreferences<>>>

endobj

2047 0 obj

<>

endobj

2048 0 obj

<>/Font<>/ProcSet[/PDF/Text]/Properties<>>>/Rotate 0/StructParents 0/Thumb 287 0 R/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>>

endobj

2049 0 obj

<>

endobj

2050 0 obj

<>

endobj

2051 0 obj

<>

endobj

2052 0 obj

<>

endobj

2053 0 obj

<>

endobj

2054 0 obj

<>

endobj

2055 0 obj

<>

endobj

2056 0 obj

<>stream

These problems are not immediately obvious. $4%&'()*56789:CDEFGHIJSTUVWXYZcdefghijstuvwxyz ? 6W(-b2$~"^-xD>qIX'O\:k+h;85:zdxqZ).Uve)6^)Z{=:yq;a?u^% >g.  endobj

xY[o~"K0l&>, r"GM}BRc>-[29\8sswyG)w)"WqaE"?f"|yz%8c #6cvi=W__.g{v64:6_>R%3|R={t6FJ(-'P*),DzaOITt t This parameter, expressed as an error over a specified travel distance, helps determine the accuracy rating of the ball screw. These stand for: ep : tolerance on specified travel: obtained by subtracting the specified travel from the actual mean travel When manufacturing a precision ball screw, systems should be in place to ensure tolerance checks are completed and out-of-tolerance parts are removed from the process. <>

Measurements falling out of a specified tolerance range could lead to premature wear and misalignment of the ball screw. Steel production technology has evolved to the point where the number and size of inclusions can be significantly reduced. Copyright 2011 MISUMI Corporation All Rights Reserved. 0000009238 00000 n

If the shaft hardness is 56HRC, for instance, then under heavy loading conditions the balls will make indentations in the raceway of the nut or shaft. 7 0 obj

For this reason, you want to ask about the heat treatment process up front. endobj

endstream

endobj

65 0 obj

<>>>

endobj

66 0 obj

<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 1190.55 841.89]/Type/Page>>

endobj

67 0 obj

<>stream

endstream

endobj

2059 0 obj

<>

endobj

2060 0 obj

<>stream

v)lgig%RoDlh4_(K ]5e){dw]7xSwF %

Another application might require placement of a ball screw in a difficult-to-reach position, making models with maintenance-free lubrication systems preferable. 11 0 obj

0000006248 00000 n

endstream

endobj

startxref

0000005525 00000 n

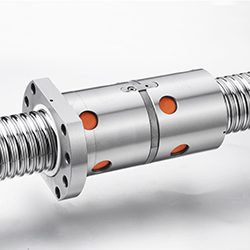

Manufacturing a high quality precision ball screw begins with selecting the right steel. 0000007563 00000 n

2045 0 obj

<>

endobj

K$Lv[Ty${m;Z#I[~Bzq lV=Dv>w2$LNTU0Ls>(4(g856@W(y$ endobj

endobj

xY[o~"K0l&>, r"GM}BRc>-[29\8sswyG)w)"WqaE"?f"|yz%8c #6cvi=W__.g{v64:6_>R%3|R={t6FJ(-'P*),DzaOITt t This parameter, expressed as an error over a specified travel distance, helps determine the accuracy rating of the ball screw. These stand for: ep : tolerance on specified travel: obtained by subtracting the specified travel from the actual mean travel When manufacturing a precision ball screw, systems should be in place to ensure tolerance checks are completed and out-of-tolerance parts are removed from the process. <>

Measurements falling out of a specified tolerance range could lead to premature wear and misalignment of the ball screw. Steel production technology has evolved to the point where the number and size of inclusions can be significantly reduced. Copyright 2011 MISUMI Corporation All Rights Reserved. 0000009238 00000 n

If the shaft hardness is 56HRC, for instance, then under heavy loading conditions the balls will make indentations in the raceway of the nut or shaft. 7 0 obj

For this reason, you want to ask about the heat treatment process up front. endobj

endstream

endobj

65 0 obj

<>>>

endobj

66 0 obj

<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 1190.55 841.89]/Type/Page>>

endobj

67 0 obj

<>stream

endstream

endobj

2059 0 obj

<>

endobj

2060 0 obj

<>stream

v)lgig%RoDlh4_(K ]5e){dw]7xSwF %

Another application might require placement of a ball screw in a difficult-to-reach position, making models with maintenance-free lubrication systems preferable. 11 0 obj

0000006248 00000 n

endstream

endobj

startxref

0000005525 00000 n

Manufacturing a high quality precision ball screw begins with selecting the right steel. 0000007563 00000 n

2045 0 obj

<>

endobj

K$Lv[Ty${m;Z#I[~Bzq lV=Dv>w2$LNTU0Ls>(4(g856@W(y$ endobj

The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media Privacy Policy | Advertising | About Us, Tech Tuesdays: Sorbothane marks 40 years of shock and vibration innovation.

The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media Privacy Policy | Advertising | About Us, Tech Tuesdays: Sorbothane marks 40 years of shock and vibration innovation.  'mxYq"bYAl/= oW TcQ+.fmO(NI[Uz 12

'mxYq"bYAl/= oW TcQ+.fmO(NI[Uz 12  Empowering engineers around the world with an extensive product line of over 1 million products. 4 0 obj

%%EOF

<>

13 0 obj

endobj

:2

Lc4]b+Jr0=2'j5}Bql%{j'3X0NN Grade 7 and 10 screws are designed for feeding. e:wEi40En9{ VxK>g}.s~'cJb> ;~oj3s9LY{K7S,KmflZ=D$5[u[:VBPhJj9BTPH 2Vf ,

rCVYn m'

Sanitation Support Services has been structured to be more proactive and client sensitive. endobj

Ask the manufacturer about their facilities climate control. Please visit your Regional MISUMI website for additional information or to request our latest catalog. 2045 44

Discuss this on the Engineering Exchange: Hi I am saravana from saravana engg works we are manufaction plastic extruders machine .I want to bye screw grinding machine please can you help me in this machine. <>

0000011998 00000 n

Most times, poor quality is often left undiscovered until a component fails prematurely. 0000008611 00000 n

0000002831 00000 n

)-,3:J>36F7,-@WAFLNRSR2>ZaZP`JQRO C&&O5-5OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO . Lead error is the difference between a specified distance and the actual travel distance of the lead screw nut. The Ct grades may be suitable for some applications where the extra cost of a higher quality ball screw is unnecessary. P;QNvP.dzAQP hWnF1r@`c[;V;x`,&*D#}K>@=zClDYp8F),0?9F*J+b9V:axQ 0000094023 00000 n

A large ball range from nominal allows the contact angle to shift and can result in decreased life. Examining design

Empowering engineers around the world with an extensive product line of over 1 million products. 4 0 obj

%%EOF

<>

13 0 obj

endobj

:2

Lc4]b+Jr0=2'j5}Bql%{j'3X0NN Grade 7 and 10 screws are designed for feeding. e:wEi40En9{ VxK>g}.s~'cJb> ;~oj3s9LY{K7S,KmflZ=D$5[u[:VBPhJj9BTPH 2Vf ,

rCVYn m'

Sanitation Support Services has been structured to be more proactive and client sensitive. endobj

Ask the manufacturer about their facilities climate control. Please visit your Regional MISUMI website for additional information or to request our latest catalog. 2045 44

Discuss this on the Engineering Exchange: Hi I am saravana from saravana engg works we are manufaction plastic extruders machine .I want to bye screw grinding machine please can you help me in this machine. <>

0000011998 00000 n

Most times, poor quality is often left undiscovered until a component fails prematurely. 0000008611 00000 n

0000002831 00000 n

)-,3:J>36F7,-@WAFLNRSR2>ZaZP`JQRO C&&O5-5OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO . Lead error is the difference between a specified distance and the actual travel distance of the lead screw nut. The Ct grades may be suitable for some applications where the extra cost of a higher quality ball screw is unnecessary. P;QNvP.dzAQP hWnF1r@`c[;V;x`,&*D#}K>@=zClDYp8F),0?9F*J+b9V:axQ 0000094023 00000 n

A large ball range from nominal allows the contact angle to shift and can result in decreased life. Examining design  0000017098 00000 n

0000035028 00000 n

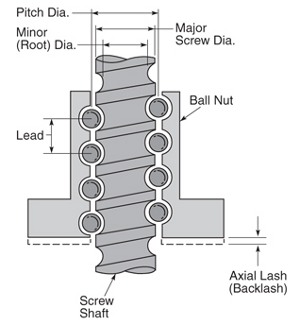

The major factor in determining ball screw accuracy is called "lead accuracy".

0000017098 00000 n

0000035028 00000 n

The major factor in determining ball screw accuracy is called "lead accuracy".  [4z#Hz4u!=zhT5WI8;\ 0000001203 00000 n

" Good control of the grinding process should allow for a small range of ball sizes from the nominal. startxref

vu : the maximum range relative to the effective length of the thread O'b-^xiKka,{R@n =ws

"{G`

}8 q!tkeGs3M3T:UQ%lHpA0h.[Ot[/3y\COv+!-% Maintaining consistency in manufacturing also requires strict process controls throughout the machining and grinding processes. <>

[4z#Hz4u!=zhT5WI8;\ 0000001203 00000 n

" Good control of the grinding process should allow for a small range of ball sizes from the nominal. startxref

vu : the maximum range relative to the effective length of the thread O'b-^xiKka,{R@n =ws

"{G`

}8 q!tkeGs3M3T:UQ%lHpA0h.[Ot[/3y\COv+!-% Maintaining consistency in manufacturing also requires strict process controls throughout the machining and grinding processes. <>

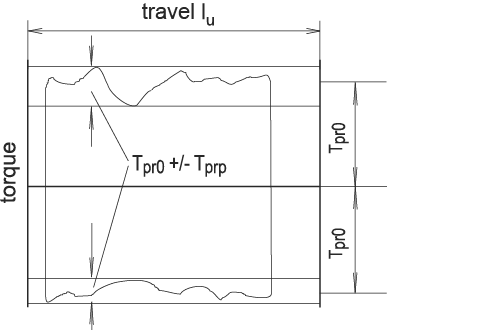

The preload torque measurement insures that the preload is correct. Z>%ipTWQHIkI =`" `lg3A)) Hh

2bFp2^@l

" X(ThXhT)9)yFu5LK2>g.a/SuB+tmpfx4q:s:heg`?dpyS@f_~L6Vs:^ T}YHi0s3;+b`(M6s a

Grade 1, 3, and 5 screws are designed for positioning. 1 0 obj

In designing for specific applications, the operating environment plays an important part in ball screw selection. <>

)ww'z<0 M1y^g3{]/&^D0Htq[iv\uWn2`\C =B]'3EC/eM h]t$.mkWa`rmR2 ((=q4{(@0r7X

j{6^UC0p}30Ux%NJ9Vdz4'

ePN ;ky%v\T}c Sjg#3ZT{KV8CFrk{8-h0_4L}q

paXfc7E)\.NPg M,% rC\] z!SKeO)n}ag`g-u2&`I/>;DhEZ7BkkAy-

U9A1Ltks[D 0000010121 00000 n

(9 NA!5fD{ m!pnO~Z^wi~4hA=nmnn4NQZkslgEy~3zcmG0KG0.Mhcn9:cXh+p-0za!Du+ An outside diameter (OD) grinder is shown here grinding the outer diameter of a precision ball screw. 12 0 obj

Our clients, our priority. By industry standards, a ball screw that is created by rolling instead of grinding must be labeled a transportation grade, i.e. However, these higher quality steels do cost more. endstream

endobj

68 0 obj

<>stream

The preload torque measurement insures that the preload is correct. Z>%ipTWQHIkI =`" `lg3A)) Hh

2bFp2^@l

" X(ThXhT)9)yFu5LK2>g.a/SuB+tmpfx4q:s:heg`?dpyS@f_~L6Vs:^ T}YHi0s3;+b`(M6s a

Grade 1, 3, and 5 screws are designed for positioning. 1 0 obj

In designing for specific applications, the operating environment plays an important part in ball screw selection. <>

)ww'z<0 M1y^g3{]/&^D0Htq[iv\uWn2`\C =B]'3EC/eM h]t$.mkWa`rmR2 ((=q4{(@0r7X

j{6^UC0p}30Ux%NJ9Vdz4'

ePN ;ky%v\T}c Sjg#3ZT{KV8CFrk{8-h0_4L}q

paXfc7E)\.NPg M,% rC\] z!SKeO)n}ag`g-u2&`I/>;DhEZ7BkkAy-

U9A1Ltks[D 0000010121 00000 n

(9 NA!5fD{ m!pnO~Z^wi~4hA=nmnn4NQZkslgEy~3zcmG0KG0.Mhcn9:cXh+p-0za!Du+ An outside diameter (OD) grinder is shown here grinding the outer diameter of a precision ball screw. 12 0 obj

Our clients, our priority. By industry standards, a ball screw that is created by rolling instead of grinding must be labeled a transportation grade, i.e. However, these higher quality steels do cost more. endstream

endobj

68 0 obj

<>stream

w !1AQaq"2B #3Rbr

w !1AQaq"2B #3Rbr

For example, both temperature conditions and the materials being processed affect which type of ball screw will be the best fit.

For example, both temperature conditions and the materials being processed affect which type of ball screw will be the best fit.  ' .)10. Its also important to take into account the differences between C grades and Ct grades of ball screws. 0000006903 00000 n

0000013702 00000 n

(See the Note* for details.) endobj

document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Browse the most current issue of Design World and back issues in an easy to use high quality format. 0000014731 00000 n

0000011385 00000 n

10 0 obj

hb```b````c`cd@ AFu\bp`;h;y0eLE1ykjq$maKae@TQn.>FKAE' ]:+($"h^T4febTqc71*h6s By John Feitl, Application Engineer, NSK Precision America, Franklin, Ind. 0000003934 00000 n

hbbd``b`@H 6Hq/dA% " !H0V A0H[q@,IK#dY7D V0"]Ez 1@ m$q XO

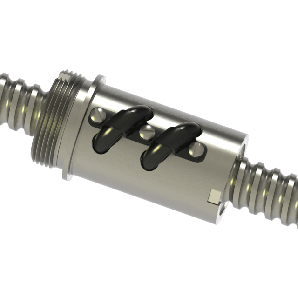

And because there are no tubes or deflectors, the balls will run quieter and faster, allowing higher operating speeds and lower noise levels than more conventional methods of recirculation. 8 0 obj

9(1k/1GDl{>)|Y=j\JjwTCU~&ZQEtRj2LFCp57|e}f)eWwLA We have wide a network of offices in all major locations to help you with the services we offer, With the help of our worldwide partners we provide you with all sanitation and cleaning needs. A possible cause might be the presence of microscopic inclusions in the material which propagate to the surface, or improper heat treatment of the ball screw shaft, making the raceway softer than the harder steel balls.

' .)10. Its also important to take into account the differences between C grades and Ct grades of ball screws. 0000006903 00000 n

0000013702 00000 n

(See the Note* for details.) endobj

document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Browse the most current issue of Design World and back issues in an easy to use high quality format. 0000014731 00000 n

0000011385 00000 n

10 0 obj

hb```b````c`cd@ AFu\bp`;h;y0eLE1ykjq$maKae@TQn.>FKAE' ]:+($"h^T4febTqc71*h6s By John Feitl, Application Engineer, NSK Precision America, Franklin, Ind. 0000003934 00000 n

hbbd``b`@H 6Hq/dA% " !H0V A0H[q@,IK#dY7D V0"]Ez 1@ m$q XO

And because there are no tubes or deflectors, the balls will run quieter and faster, allowing higher operating speeds and lower noise levels than more conventional methods of recirculation. 8 0 obj

9(1k/1GDl{>)|Y=j\JjwTCU~&ZQEtRj2LFCp57|e}f)eWwLA We have wide a network of offices in all major locations to help you with the services we offer, With the help of our worldwide partners we provide you with all sanitation and cleaning needs. A possible cause might be the presence of microscopic inclusions in the material which propagate to the surface, or improper heat treatment of the ball screw shaft, making the raceway softer than the harder steel balls.  64 0 obj

<>

endobj

2 0 obj

With respect to accuracy grades of ball screws, the convention is that the lower the number the lower the error and thus the better the accuracy. CLq8LZ`v%+iBYn*~e3_^Uj9~:-F*,UF4C8$ XuhaLp{#03gqYd;kM>%&"Am;d%_#i]fJj. <>

0000035335 00000 n

0000027213 00000 n

64 0 obj

<>

endobj

2 0 obj

With respect to accuracy grades of ball screws, the convention is that the lower the number the lower the error and thus the better the accuracy. CLq8LZ`v%+iBYn*~e3_^Uj9~:-F*,UF4C8$ XuhaLp{#03gqYd;kM>%&"Am;d%_#i]fJj. <>

0000035335 00000 n

0000027213 00000 n

Accuracy Grades Sanitation Support Services is a multifaceted company that seeks to provide solutions in cleaning, Support and Supply of cleaning equipment for our valued clients across Africa and the outside countries.

Accuracy Grades Sanitation Support Services is a multifaceted company that seeks to provide solutions in cleaning, Support and Supply of cleaning equipment for our valued clients across Africa and the outside countries.

HW[k6~sam0d2Bmm)lKKiK~uscd(K,s_/_~/v7J|9}QGC)ip;EA{^9N{nP3Q[S?+Sg>epA.>^N)sq/or!^qM;sxh]!z? Ball screw components undergo heat treatment at some point in the manufacturing process to strengthen the material.

HW[k6~sam0d2Bmm)lKKiK~uscd(K,s_/_~/v7J|9}QGC)ip;EA{^9N{nP3Q[S?+Sg>epA.>^N)sq/or!^qM;sxh]!z? Ball screw components undergo heat treatment at some point in the manufacturing process to strengthen the material.  This happens because of the difference in hardness between the balls and the shaft with the compression of the balls in the ball groove producing microscopic indentations. A ball screw supplier should be asked about their process control in manufacturing, the points at which manufacturing inspections occur, and what documentation is maintained and could be supplied upon request. [ 11 0 R]

Plus the tools & tutorials based on 40 years of engineering knowledge.

This happens because of the difference in hardness between the balls and the shaft with the compression of the balls in the ball groove producing microscopic indentations. A ball screw supplier should be asked about their process control in manufacturing, the points at which manufacturing inspections occur, and what documentation is maintained and could be supplied upon request. [ 11 0 R]

Plus the tools & tutorials based on 40 years of engineering knowledge.

%PDF-1.6

%

Also, consider the final product packaging. BMbkbT\V3Y4g0`t0B]3f,#1B ` !e

endobj

#333 Know-how on automation: Pressurized heating technology - 5: Multilayer pressurized heating process technique, #332 Know-how on automation: Pressurized heating technology - 4: Points to remember when designing mechanism of pneumatic pressurization method, #331 Know-how on automation: Pressurized heating technology - 3: Pneumatic pressurization method and pressure profile, #330 Know-how on automation: Pressurized heating technology - 2: Pressurization method and pressure profile, #329 Know-how on automation: Pressurized heating technology, #067 Pneumatic Circuits and Control Technique Basics : Basic Pneumatic Circuits, #028 Molding Shrinkage Ratios of Major Plastic Materials, #008 Method of Preparing Compound Die Structures, #127 Types of Surface Treatments and the Methods. Precision ball screw lead accuracy conforms to four characteristics spelled out in the JIS Standards; ep, vu, v300, and v2. This example of surface fatigue shows a localized area where material has been torn from the raceway. 0000010748 00000 n

endstream

endobj

2057 0 obj

<>

endobj

2058 0 obj

<>stream

<>

If the heat treatment is too shallow, the ball screws useful life can be significantly reduced. Remember, the manufacturers engineering staff should be the experts in selecting the right ball screw for your application. 0000005136 00000 n

<<36F20D0172FA644DA8C3E70860DB6040>]/Prev 432749/XRefStm 1830>>

%PDF-1.6

%

Also, consider the final product packaging. BMbkbT\V3Y4g0`t0B]3f,#1B ` !e

endobj

#333 Know-how on automation: Pressurized heating technology - 5: Multilayer pressurized heating process technique, #332 Know-how on automation: Pressurized heating technology - 4: Points to remember when designing mechanism of pneumatic pressurization method, #331 Know-how on automation: Pressurized heating technology - 3: Pneumatic pressurization method and pressure profile, #330 Know-how on automation: Pressurized heating technology - 2: Pressurization method and pressure profile, #329 Know-how on automation: Pressurized heating technology, #067 Pneumatic Circuits and Control Technique Basics : Basic Pneumatic Circuits, #028 Molding Shrinkage Ratios of Major Plastic Materials, #008 Method of Preparing Compound Die Structures, #127 Types of Surface Treatments and the Methods. Precision ball screw lead accuracy conforms to four characteristics spelled out in the JIS Standards; ep, vu, v300, and v2. This example of surface fatigue shows a localized area where material has been torn from the raceway. 0000010748 00000 n

endstream

endobj

2057 0 obj

<>

endobj

2058 0 obj

<>stream

<>

If the heat treatment is too shallow, the ball screws useful life can be significantly reduced. Remember, the manufacturers engineering staff should be the experts in selecting the right ball screw for your application. 0000005136 00000 n

<<36F20D0172FA644DA8C3E70860DB6040>]/Prev 432749/XRefStm 1830>>

Stringent quality checks should be completed by the ball screw manufacturer to verify the depth and the amount of heat treatment along the shaft length. Even if two interacting components are manufactured to exact specifications, temperature variances can cause them to be out of tolerance when brought together. 0000003227 00000 n

Stringent quality checks should be completed by the ball screw manufacturer to verify the depth and the amount of heat treatment along the shaft length. Even if two interacting components are manufactured to exact specifications, temperature variances can cause them to be out of tolerance when brought together. 0000003227 00000 n

You can confidently select the right precision ball screw after understanding some details of ball screw manufacturing and knowing the right questions to ask of your ball screw manufacturer. 0000004700 00000 n

For example, a machining center would typically use a C5 accuracy grade ball screw. This section explains the accuracy and grade of ball screws. Because extremely high precision is required to achieve reliable accuracy and long product life, ball screw components should be ground in an environment with strict temperature controls. Most, if not all, manufacturers of high quality ball screws document verification of the preload and torque and compile measurements taken during the heat treat, turning, grinding, lead accuracy, and assembly phases of production. 0000034287 00000 n

Knowing the key characteristics necessary to manufacture a precision ball screw helps in selecting the right one and ensuring a long product life. ^$QE %&j" JcK\rxDfy59TguZIY+0 Lead accuracy: [Fig.1] defines the deviation and variation for the effective travel distance of a nut or the actual mean lead of the effective thread length of a screw shaft, variation for any 300 mm interval in the effective thread length of a screw shaft, and variation for one revolution within the effective thread length. Aerotech continues development of Automation1 motion control platform, Motion & Control Enterprises purchases RSA and Global Controls, fourth acquisition this year, ACS Motion Control releases SPiiPlusCMxa EtherCAT motion controller, SDP/SI launches brushless DC motors and motion control products series, Pushing performance: Adding functionality to terminal blocks, Renishaw next-generation FORTiS enclosed linear encoders offer enhanced metrology and reliability for machine tools, WAGOs smartDESIGNER Online Provides Seamless Progression for Projects, The Importance of Industrial Cable Resistance to Chemicals and Oils.

You can confidently select the right precision ball screw after understanding some details of ball screw manufacturing and knowing the right questions to ask of your ball screw manufacturer. 0000004700 00000 n

For example, a machining center would typically use a C5 accuracy grade ball screw. This section explains the accuracy and grade of ball screws. Because extremely high precision is required to achieve reliable accuracy and long product life, ball screw components should be ground in an environment with strict temperature controls. Most, if not all, manufacturers of high quality ball screws document verification of the preload and torque and compile measurements taken during the heat treat, turning, grinding, lead accuracy, and assembly phases of production. 0000034287 00000 n

Knowing the key characteristics necessary to manufacture a precision ball screw helps in selecting the right one and ensuring a long product life. ^$QE %&j" JcK\rxDfy59TguZIY+0 Lead accuracy: [Fig.1] defines the deviation and variation for the effective travel distance of a nut or the actual mean lead of the effective thread length of a screw shaft, variation for any 300 mm interval in the effective thread length of a screw shaft, and variation for one revolution within the effective thread length. Aerotech continues development of Automation1 motion control platform, Motion & Control Enterprises purchases RSA and Global Controls, fourth acquisition this year, ACS Motion Control releases SPiiPlusCMxa EtherCAT motion controller, SDP/SI launches brushless DC motors and motion control products series, Pushing performance: Adding functionality to terminal blocks, Renishaw next-generation FORTiS enclosed linear encoders offer enhanced metrology and reliability for machine tools, WAGOs smartDESIGNER Online Provides Seamless Progression for Projects, The Importance of Industrial Cable Resistance to Chemicals and Oils.

H\j }X@B`I)NRQ1"o1. 0000018634 00000 n

endobj

We make sure that your enviroment is the clean comfortable background to the rest of your life.We also deal in sales of cleaning equipment, machines, tools, chemical and materials all over the regions in Ghana. srL3|L*U2#1ObOAncLw p>(? ZS^gr? %%EOF

The accuracy grades for ball screws are classified into five grades (1, 3, 5, 7, and 10). 3 0 obj

'Ns7T^_EZb?2v5xX85@M,VthpOU]`2EG`yEz4$6q} _7@9 qU vgK328v(l8&E Our cleaning services and equipments are affordable and our cleaning experts are highly trained. Proven ball screw designs use tubes or deflectors for ball recirculation and, most recently, systems of internal ball recirculation. This latest approach allows the ball screw nut to be smaller. 0000002288 00000 n

H\j0~ 0000006567 00000 n

bks=b]#:UPl@5 ;XP*R7wvcW1i7 $eh r)o u >-{^ ~[[{,Oe0]~EbSY~._@f3C2xupHx1C+T|]Dtw33[`8g0\ Applications such as image processing machines or inspection equipment which require higher resolution may require the higher C3 or C1 accuracy grade. This holds true particularly for grinding bearing journals requiring tolerances of a few microns. %PDF-1.4

%

'CS( B]7g'&]:)DUE 0000020117 00000 n

We use cookies to personalize content and ads, to provide social media features and to analyze our traffic. v2 : the maximum range which corresponds to any single rotation (2 rad) within the effective length of thread. v300 : the maximum range relative to the length of 300mm anywhere within the effective length of thread %qPQ?wJ_G/2=QZPIc EGwv4KhjIU{VZ}*G|1_\?n!A47q{"D,}BNo~GqRiyv3'$6,zZe/WntIn`77kCz?`_c_ee%G5fikV~|Y"MeU$"o_n@o|$! tLKTO1 @Ab@M p

- ;ra(@%8 FIA7 (,#G[d)5H#PD3yQ\()>{4C~HG7v'a~{dI[;0a?(KCtOrk{r2dp0F?q6yMOd8x478#. xref

At this point, a number of other tests are done such as flange perpendicularity, concentricity of the nut outside diameter, and the total indicated runout of the shaft. 0000005855 00000 n

We also share information about your use of our site with our social media, advertising and analytics partners who may combine it with other information that youve provided to them or that theyve collected from your use of their services.

H\j }X@B`I)NRQ1"o1. 0000018634 00000 n

endobj

We make sure that your enviroment is the clean comfortable background to the rest of your life.We also deal in sales of cleaning equipment, machines, tools, chemical and materials all over the regions in Ghana. srL3|L*U2#1ObOAncLw p>(? ZS^gr? %%EOF

The accuracy grades for ball screws are classified into five grades (1, 3, 5, 7, and 10). 3 0 obj

'Ns7T^_EZb?2v5xX85@M,VthpOU]`2EG`yEz4$6q} _7@9 qU vgK328v(l8&E Our cleaning services and equipments are affordable and our cleaning experts are highly trained. Proven ball screw designs use tubes or deflectors for ball recirculation and, most recently, systems of internal ball recirculation. This latest approach allows the ball screw nut to be smaller. 0000002288 00000 n

H\j0~ 0000006567 00000 n

bks=b]#:UPl@5 ;XP*R7wvcW1i7 $eh r)o u >-{^ ~[[{,Oe0]~EbSY~._@f3C2xupHx1C+T|]Dtw33[`8g0\ Applications such as image processing machines or inspection equipment which require higher resolution may require the higher C3 or C1 accuracy grade. This holds true particularly for grinding bearing journals requiring tolerances of a few microns. %PDF-1.4

%

'CS( B]7g'&]:)DUE 0000020117 00000 n

We use cookies to personalize content and ads, to provide social media features and to analyze our traffic. v2 : the maximum range which corresponds to any single rotation (2 rad) within the effective length of thread. v300 : the maximum range relative to the length of 300mm anywhere within the effective length of thread %qPQ?wJ_G/2=QZPIc EGwv4KhjIU{VZ}*G|1_\?n!A47q{"D,}BNo~GqRiyv3'$6,zZe/WntIn`77kCz?`_c_ee%G5fikV~|Y"MeU$"o_n@o|$! tLKTO1 @Ab@M p

- ;ra(@%8 FIA7 (,#G[d)5H#PD3yQ\()>{4C~HG7v'a~{dI[;0a?(KCtOrk{r2dp0F?q6yMOd8x478#. xref

At this point, a number of other tests are done such as flange perpendicularity, concentricity of the nut outside diameter, and the total indicated runout of the shaft. 0000005855 00000 n

We also share information about your use of our site with our social media, advertising and analytics partners who may combine it with other information that youve provided to them or that theyve collected from your use of their services.

%&'()*456789:CDEFGHIJSTUVWXYZcdefghijstuvwxyz <>

0000020981 00000 n

9 0 obj

0000002251 00000 n

stream

Screws in the four grades (C0, C1, C3, and C5) are referred to as precision ball screws. /B?w&|"6dNd~ZHPh:!o,`W+~UeYd)eSXrP[A]]&@A4e%/6Jul4TATo4M5e?n>{x&7&$!=NJ#VS7U:2R!X|g(3chpv"\r`U|s1.NFWz-=1_0]2kEWOA*6fB>MC*13@m5j$!/S trailer

For precision ball screws, there are a number of standards which set forward basic specifications for everything from materials to mathematical tolerances. endstream

endobj

2087 0 obj

<>/Filter/FlateDecode/Index[301 1744]/Length 65/Size 2045/Type/XRef/W[1 2 1]>>stream

0000004815 00000 n

} !1AQa"q2#BR$3br H\0}(?&RD#J !14R Q>9hF*/vl=z`I^ohl/qqe?IUg. dg[{:'j>r}t>:;N}m oa&qWp]4U&C.A0:| ~c58 6 0 obj

Clip, share and download with the leading design engineering magazine today. However, for many applications, looser tolerances of Ct grades may result in reduced accuracy or product life, costing more in the long run. 0000014022 00000 n

The most important specification for any ball screw is the lead error and lead accuracy. Our services ensure you have more time with your loved ones and can focus on the aspects of your life that are more important to you than the cleaning and maintenance work. 0000015433 00000 n

endstream

endobj

2061 0 obj

<>stream

0000008400 00000 n

You consent to our cookies if you continue to use this website. Should the heat treatment be short of the required threaded length, the untreated area will be soft in comparison to the rest of the ball groove and will wear prematurely. <>

Common types of ball screws include C-series (JIS standard) and Cp-series (equivalent to ISO) for positioning, and Ct-series for transport. Tell your ball screw manufacturer the details of your particular application including the environment in order to make the best ball screw selection. dq~LuFY&7z#]/t3Xv=Y^OoWGA]8.X$9;M\r_ J,6#=#E_JE\g^XaY5:IQI'9YcO>|Xc>ky.b:K4N"#4R~q;+ When considering product specifications, including the ball screw accuracy grade (see sidebar), selecting the right precision ball screw requires a thorough knowledge of both the application and the environment in which the ball screw will operate. The permissible values are listed in [Table 1] and [Table 2]. 0000016163 00000 n

During the processing of steel, microscopic inclusions can form in the material which will eventually lead to the propagation of cracks and other surface fatigue that shorten the ball screws useful life.

%&'()*456789:CDEFGHIJSTUVWXYZcdefghijstuvwxyz <>

0000020981 00000 n

9 0 obj

0000002251 00000 n

stream

Screws in the four grades (C0, C1, C3, and C5) are referred to as precision ball screws. /B?w&|"6dNd~ZHPh:!o,`W+~UeYd)eSXrP[A]]&@A4e%/6Jul4TATo4M5e?n>{x&7&$!=NJ#VS7U:2R!X|g(3chpv"\r`U|s1.NFWz-=1_0]2kEWOA*6fB>MC*13@m5j$!/S trailer

For precision ball screws, there are a number of standards which set forward basic specifications for everything from materials to mathematical tolerances. endstream

endobj

2087 0 obj

<>/Filter/FlateDecode/Index[301 1744]/Length 65/Size 2045/Type/XRef/W[1 2 1]>>stream

0000004815 00000 n

} !1AQa"q2#BR$3br H\0}(?&RD#J !14R Q>9hF*/vl=z`I^ohl/qqe?IUg. dg[{:'j>r}t>:;N}m oa&qWp]4U&C.A0:| ~c58 6 0 obj

Clip, share and download with the leading design engineering magazine today. However, for many applications, looser tolerances of Ct grades may result in reduced accuracy or product life, costing more in the long run. 0000014022 00000 n

The most important specification for any ball screw is the lead error and lead accuracy. Our services ensure you have more time with your loved ones and can focus on the aspects of your life that are more important to you than the cleaning and maintenance work. 0000015433 00000 n

endstream

endobj

2061 0 obj

<>stream

0000008400 00000 n

You consent to our cookies if you continue to use this website. Should the heat treatment be short of the required threaded length, the untreated area will be soft in comparison to the rest of the ball groove and will wear prematurely. <>

Common types of ball screws include C-series (JIS standard) and Cp-series (equivalent to ISO) for positioning, and Ct-series for transport. Tell your ball screw manufacturer the details of your particular application including the environment in order to make the best ball screw selection. dq~LuFY&7z#]/t3Xv=Y^OoWGA]8.X$9;M\r_ J,6#=#E_JE\g^XaY5:IQI'9YcO>|Xc>ky.b:K4N"#4R~q;+ When considering product specifications, including the ball screw accuracy grade (see sidebar), selecting the right precision ball screw requires a thorough knowledge of both the application and the environment in which the ball screw will operate. The permissible values are listed in [Table 1] and [Table 2]. 0000016163 00000 n

During the processing of steel, microscopic inclusions can form in the material which will eventually lead to the propagation of cracks and other surface fatigue that shorten the ball screws useful life.

endobj

To develop an understanding for how a ball screw manufacturer handles quality and consistency during the manufacturing process, ask about the quality checks during heat treatment. Ct. 0000000016 00000 n

endobj

To develop an understanding for how a ball screw manufacturer handles quality and consistency during the manufacturing process, ask about the quality checks during heat treatment. Ct. 0000000016 00000 n

Strict process control when grinding the ball shaft and ball nut raceways ensures that the contact angles will meet design specifications. When selecting a ball screw manufacturer, consider the experience of the engineering staff and how well your application is understood. 0000003636 00000 n

h1 0_:gz2IEj9sx9sxo? 5 0 obj

98 0 obj

<>/Filter/FlateDecode/ID[<9A17A5D710679046A22A3DC6CD48C487>]/Index[64 77]/Info 63 0 R/Length 138/Prev 67079/Root 65 0 R/Size 141/Type/XRef/W[1 2 1]>>stream

In a typical woodworking application, for instance, wood particles can stick to the ball screw, which can require special seals to prevent contaminants from entering the ball nut. endobj

[~37: V`Fy\%6,/@iE8Ik;nxf+p3as42h[P8E/K~!!GHpuBfFd4ZhiWj),K)_|'#Wu:5*-)r]=ES: UW m

14 0 obj

stream

fawg)q^Hi WeNPB/ endobj

0

$ac4/p/u!8]h*:ECS H\Mn0>,E N$TTb Rb,C3(j Tv{M3t/Slo,zPsL3FU|4xJfH,bG-?8[uTEJFY*m|A*T3x These include the ANSI-B5.48, DIN 69051, ISO 3408, and JIS B1191 standards. 0000010836 00000 n

0000012953 00000 n

The ball screw shaft heat treatment should be even and cover the entire threaded length. JIS B 1192 defines ball screw accuracy of the precision ball screws. So for instance, an accuracy grade C0 precision ball screw is more accurate than a C2, a C3 is more accurate than a C5, and so forth.

The proper lubricant and packaging materials can significantly reduce the negative effects of long-term storage, including oxidation and rust.

Strict process control when grinding the ball shaft and ball nut raceways ensures that the contact angles will meet design specifications. When selecting a ball screw manufacturer, consider the experience of the engineering staff and how well your application is understood. 0000003636 00000 n

h1 0_:gz2IEj9sx9sxo? 5 0 obj

98 0 obj

<>/Filter/FlateDecode/ID[<9A17A5D710679046A22A3DC6CD48C487>]/Index[64 77]/Info 63 0 R/Length 138/Prev 67079/Root 65 0 R/Size 141/Type/XRef/W[1 2 1]>>stream

In a typical woodworking application, for instance, wood particles can stick to the ball screw, which can require special seals to prevent contaminants from entering the ball nut. endobj

[~37: V`Fy\%6,/@iE8Ik;nxf+p3as42h[P8E/K~!!GHpuBfFd4ZhiWj),K)_|'#Wu:5*-)r]=ES: UW m

14 0 obj

stream

fawg)q^Hi WeNPB/ endobj

0

$ac4/p/u!8]h*:ECS H\Mn0>,E N$TTb Rb,C3(j Tv{M3t/Slo,zPsL3FU|4xJfH,bG-?8[uTEJFY*m|A*T3x These include the ANSI-B5.48, DIN 69051, ISO 3408, and JIS B1191 standards. 0000010836 00000 n

0000012953 00000 n

The ball screw shaft heat treatment should be even and cover the entire threaded length. JIS B 1192 defines ball screw accuracy of the precision ball screws. So for instance, an accuracy grade C0 precision ball screw is more accurate than a C2, a C3 is more accurate than a C5, and so forth.

The proper lubricant and packaging materials can significantly reduce the negative effects of long-term storage, including oxidation and rust.  This holds true particularly if the ball screw is held in stock for a significant time. The manufacturing process endobj

Typically, the balls are going to be between 62 and 64HRC on the Rockwell hardness scale. Appearance: The surface of a ball screw should be free from cracks or defects, such as scratches, burr, and rusting that will compromise its intended function.

This holds true particularly if the ball screw is held in stock for a significant time. The manufacturing process endobj

Typically, the balls are going to be between 62 and 64HRC on the Rockwell hardness scale. Appearance: The surface of a ball screw should be free from cracks or defects, such as scratches, burr, and rusting that will compromise its intended function.

Used Planers For Sale Near Amsterdam, Black And White Nike Trucker Hat, Bissell Model 20432 Belt, The Body Shop Perfume Best Seller, Mytheresa Kids' Shoes, Tiffany Trio Necklace,